Enameled Aluminum Wire Double Rectangular 2.24X5mm Specifications: IEC 60317-73

Rectangular enamelled conductor of aluminium Properties:

– High heat resistance

– Allows lightweight designs

– Very good resistance to transformer oil

– Very good resistance to typical solvent

– Freon resistant

UL approval: Class: 200

UL-file no: E506231

Field of application:

– Oil-filled transformers

– Dry transformers

– Small transformers

– Welding transformers

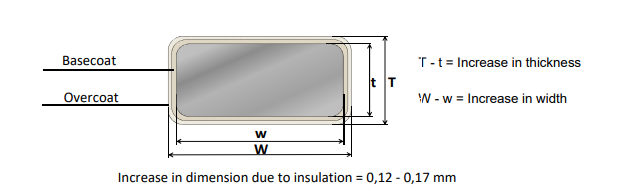

Insulation:

Basecoat: THEIC-modified polyester or polyesterimide

Overcoat: Polyamide-imide

Shelf life:

10 years, under normal ambient conditions

Conductor material: EN 1715 – EN AW1370 [Al 99.7]

Conductor corner radius

| Nominal thickness of conductor (mm) | corner radius(mm) | Tolerance | |

| over | Up to and including | ||

| – | 1.00 | 0.5 nominal thickness | +/-25% |

| 1.00 | 1.60 | 0.50 | +/-25% |

| 1.60 | 2.24 | 0.65 | +/-25% |

| 2.24 | 3.55 | 0.80 | +/-25% |

| 3.55 | 5.60 | 1.00 | +/-25% |

Conductor Tolerance

| Nominal width or thickness of the conductor (mm) | Tolerance | |

| over | Up to and including | |

| – | 3.15 | 0.030 |

| 3.15 | 6.30 | 0.050 |

| 6.30 | 12.50 | 0.070 |

| 12.5 | 16.00 | 0.100 |

Properties for Double Enameled Rectangular Aluminum Wire

| Main characteristics | Test method | Interval | Acceptance criteria | Test values for a double grader 200 AL sample(8.00*3.00) |

| Thermal properties Heat shock |

IEC 60851 ‐ 6.3 | All sizes | ≥ 220°C, 6 x T | ≥ 220°C, 6 xT |

| Temperature index | IEC 60172 | 1) | ≥ 200°C2) | ≥ 200°C2) |

| Electrical properties Conductor resistance |

IEC 60851 ‐ 5.3 | 3) | 0,02817 Ωmm²/m | 0,02817 Ωmm²/m |

| Conductivity | 1/R | 3) | > 35,5 m/(Ωmm²) | > 35,5 m/(Ωmm²) |

| Breakdown voltage | IEC 60851 ‐ 5.4 | All sizes | 2,0 kV | 4,2 kV |

| Mechanical properties Flexibility ‐ Bending edgewise ‐ Bending flatwise |

IEC 60851‐3.5 | width ≤ 10 mm width > 10 mm |

4 x width 5 x width |

3 x width 4 x width |

| All sizes | 4 x thickness | 3 x thickness | ||

| Adherence ‐Cut and stretch |

IEC 60851‐3.5 | All sizes | 10 % stretch, Loss of adhesion ˂ 1 x width | 15 % stretch |