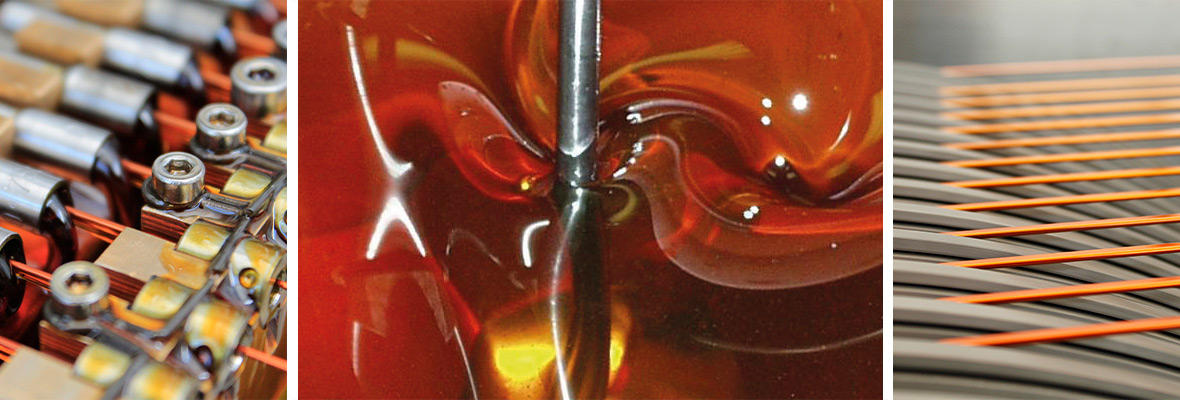

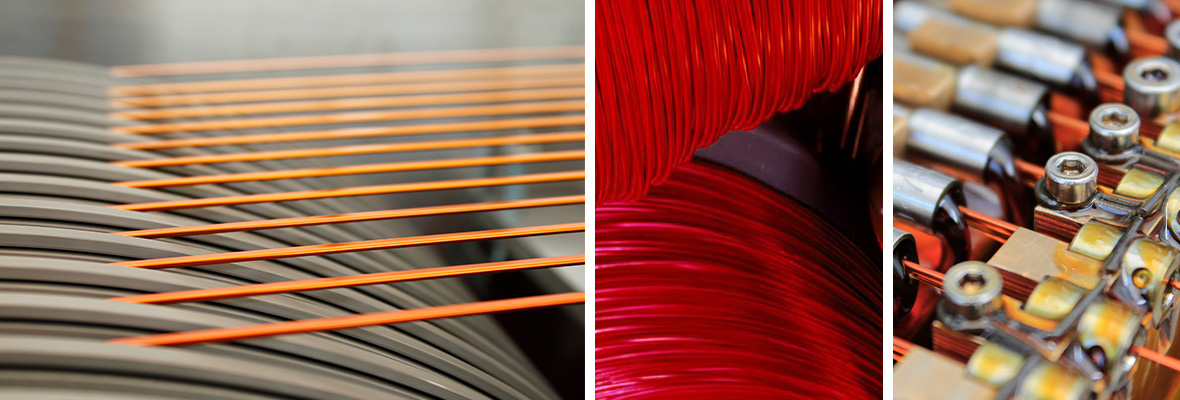

Lacquered wire enamel can be applied to up to 30 layers of copper and aluminum wire. This provides electrical insulation and helps to short-circuit the windings. These enameled wire paints must also have very good chemical and heat resistance, must adhere well to copper or aluminum wire, and have excellent mechanical stability. In some cases, such as when used in inverter-driven motors, the appropriate insulation should be resistant to possible partial discharge, which may lead to short circuit and failure of the motor. The importance of the use of polyamide-imide enamel as a paint wrap is highlighted here.

Polyamide-imide enamel is a multifunctional high performance polymer used as primary electrical insulation. They can be synthesized by three well-established methods, only two of which are commercially developed. Outstanding features include high thermal performance, chemical and wear resistance, and low friction coefficient. Other industries rely on these same properties for paints, extrusions and films. Discuss recent developments and review future trends and product offering data. The development of coatings including corona resistant enamels, self-lubricating and high wear resistance provides opportunities for further innovation in magnetic wire coatings.

Polyamide-imide enamel can be used as a double or single layer, with a choice of thickness from 0.05 to 2.6mm. The coating provides excellent protection for magnetic lines at around 180 degrees. The series of coatings have excellent heat resistance, mechanical and chemical resistance, and are good at coping with heat shock and high resistance pressure. In addition to the classic polyamide-imide coating, the product is generally mixed with an integrated lubricant to improve winding speed. These products are specially designed for use in winding wires used in dry transformers, generators and power tool motors. For flat wire applications, large transformers and high voltage equipment, polyamide-based magnetic wires are recommended for assembly. It can be used in combination with a polyester or polyester imide primer as a flexible top coat to improve the mechanical, chemical and thermal properties of the coating. In some cases, it can also be used as a single coating for copper and aluminum flat wire applications.