Thermoplastic Film

Thermoplastic film is a film made of thermoplastic resin as the base material. Such as polyethylene film, polypropylene film, polyvinyl chloride film, etc.

Read more

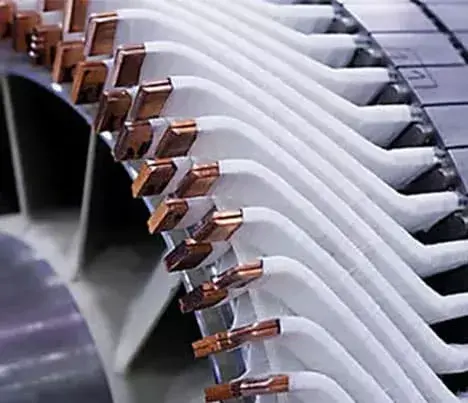

Materials is important for enameled wire, affect the quality and characteristics of magnet wire, like conductor, enamel insulation and insulation building.

Thermoplastic film is a film made of thermoplastic resin as the base material. Such as polyethylene film, polypropylene film, polyvinyl chloride film, etc.

Read more

Polyamideimide enamel is popular insulation materials for enameled wire used for transformer & motor windings, thermal class is 180C or 200C.

Read more

Kapton enamel is designed for covering enameled wire and various electric heating applications.

Read more

Bondable enamels refer to specialized enamel coatings that can adhere to a substrate and subsequently bond with another layer or material, such as adhesives, laminates,

Read more

Polyesterimide (PEI) enamel is a type of insulating coating used on enameled wires, which are wires coated with a thin layer of enamel to provide

Read more

High temperature kraft paper is a tough water resistant packaging paper with low density and high physical strength, which can provide protection for enameled wire.

Read more

Polyester glass fiber for enameled wire refers to a combination of polyester insulation and a glass fiber sheath used as an additional layer of reinforcement

Read more

Copper Clad Aluminum (CCA) Wire is a type of electrical wire made by coating an aluminum core with a thin layer of copper. This design

Read more

Aluminum wire refer to conductive bodies made primarily from aluminum. Aluminum is a lightweight, soft, and highly ductile metallic element with good electrical conductivity and

Read more

According to low temperature resistance level (105°C, 120°C), Polyvinyl Acetal/Formal Enamel wire is widely used in oil-immersed transformers due to its excellent high temperature hydrolysis

Read more

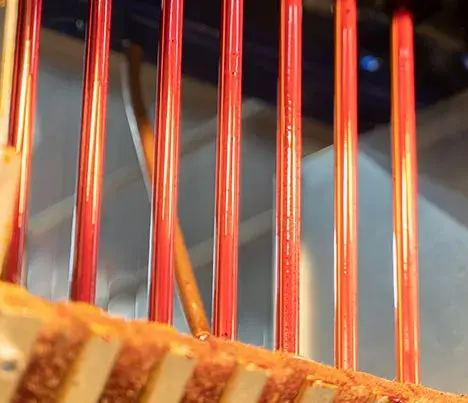

Pure copper conductor is widely used in electrical, light industry, machinery manufacturing, construction industry, national defense industry and other fields.

Read more