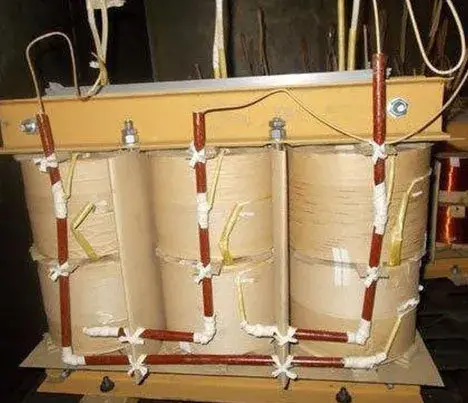

ZhengZhou LP Industry is providing high quality enameled kraft wire to electrical manufacturers in Europe, America and Asia. The low cost and high efficiency make high temperature kraft paper attractive to more customers in the electrical field. Choosing the right wire insulation material can effectively improve the work efficiency.

Why Use magnet wire insulating paper?

Enameled wire is coated with a thin polymer film. While excellent for space-saving and basic electrical isolation, this primary insulation can be vulnerable. Adding a layer of electrical insulating paper provides:

Enhanced Dielectric Strength: It significantly increases the breakdown voltage between adjacent enameled wires or between coils and the grounded core, preventing short circuits.

Mechanical Protection: The paper acts as a cushion, protecting the delicate enamel coating from abrasion, scratches, and physical stress during the winding process and operational vibration.

Thermal Resistance & Stability: Specialized insulating papers can withstand high operating temperatures, preventing thermal degradation and maintaining insulation integrity.

Environmental Sealing: It helps block moisture, oil, and contaminants from reaching the conductive copper or aluminum, reducing the risk of corrosion and tracking.

Structural Integrity: In transformers and motors, paper helps hold windings in place, providing superior dimensional stability.