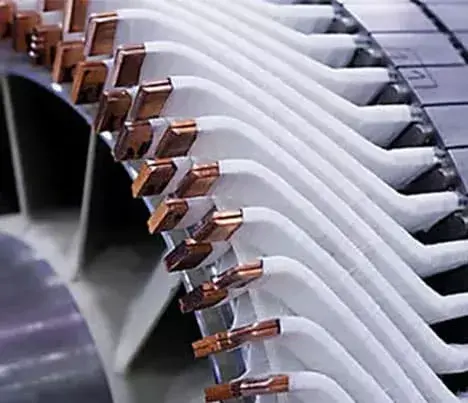

Paper Covered Enameled Copper Wire

Paper covered enameled copper wire (PCECW) is a type of insulated wire used extensively in electrical engineering and electromechanical applications, particularly in the winding of transformers, motors, and reactors. This wire combines the excellent conductivity of copper with robust insulation layers of enamel and paper.

Our Specifications

| Name | Insulation Paper Winding Wire | |

| Dimension | Round | Rectangular |

| Diameter: 1.0~7.0mm | Thickness(a): 1.0~10.0mm; Width(b): 3.0~20.0mm |

|

| Insulation Paper type | Kraft electrica paper / Nomex paper / HPI-Green / Mark paper.ect. | |

| Insulation thickness | Single, double or according to your requirement | |

| Standard | IEC,NEMA,GB,JIS | |

| Packing | 30kg~150kg Poly-wooden spool (250*500/ 250*600 | |

| Appication | Oil-immersed transformer windings;medium and alrge | |

Increase in dimensions due to paper covering

The increase in width or thickness due to the paper tape covering shall be agreed between purchaser and supplier and the minus tolerance shall not exceed the values given in follow table. The increase in width due to the paper covering shall be equal to or less than the increase in thickness.

The maximum increase may be exceeded, provided that the maximum overall dimension does not exceed the sum of the maximum dimensions of the conductor plus the maximum increase

given in follow table.

| Increase in dimension due to the paper coveringmm | Tolerance % | |

| Over | Up to and including | |

| – | 0.50 | -100 |

| 0,50 | 1,25 | -7,50 |

| 1,25 | – | -50 |

Your requirement list should includes

Insulation material: with or without enamel

Enamel material:

Paper: The number of paper tapes, type of paper, paper tape thickness. and the degree of overlap shall be agreed upon between the purchaser and supplier.

Flat type: nominal conductor dimensions in millimetres (width x thickness);

Round Type: conductor diameter

nominal increase in dimensions due to paper; Or

EXAMPLE 1

4.00x 1.00+ 0.20

– (eventually) proof strength minimum (and maximum) value.

EXAMPLE2 IEC 60317-27-3 4.00x 1.00 + 0.20 lEC 60317-27 7.00×2.50+ 1.00Rpo.2= 150 MPa

Thermal class

Appearance requirements of our enameled wire

The conductor shall be essentially free from copper dust and other extraneous matter when examined with normal vision, as wound on the original spool or reel. The paper covering shall be of one or more tapes wrapped firmly, closely, evenly, and continuously around the conductor.

No bonding or adhesive material shall be used except to anchor the ends of paper tapes.

Uses

Transformers: Power Transformers, Distribution Transformers

High-Voltage Motors: Industrial Motors, Traction Motors

Generators: Hydropower Generators, Thermal Power Generators

Reactors and Chokes: Inductive Reactors, Filter Chokes

Electromagnetic Coils: High-Voltage Coils, Specialized Inductors

Oil-Immersed Equipment: Oil-Filled Transformers, Oil-Immersed Reactors

Power Supply Units: High-Power Inverters, Converters

Magnetic Amplifiers: Control and Amplification Systems

Heavy Electrical Equipment: Industrial Machinery