Glass Fibre Wound Enamelled Rectangular Copper Wire, Temperature Index 155

Glass fibre wound enamelled rectangular copper wire is a specialized electrical enamelled wire. It is known for its enhanced mechanical and thermal properties. The addition of glass fibre winding provides additional strength and protection.

Over the enamelled copper wire, glass fibre is wound. Glass fibre adds mechanical strength and significantly enhances the thermal resistance of the wire. It is particularly useful in high-temperature applications and provides additional protection against abrasion and mechanical damage.

Glass fibre winding involves wrapping the copper wire with a layer of glass fibre. This layer serves as additional insulation and mechanical protection, enhancing the wire’s durability and resistance to thermal and mechanical stress. Glass fibre is high tensile strength and resistance to high temperatures.

Temperature index 155

The temperature index of 155 signifies that the wire can operate reliably at temperatures up to 155°C. And it without significant degradation of its insulating properties. This rating is crucial for applications involving high thermal loads, ensuring long-term performance and safety.

The temperature index is a measure of the thermal endurance of an insulating material. It indicates the maximum temperature at which the material can operate continuously without significant loss of its insulating properties over a specified period.

Winding wire

The enamelled wire shall have a temperature index of at least 155 and shall be agreed between purchaser and supplier.

The temperature index of the wire is dependent upon the type of impregnating agent used. The impregnating agent applied to the glass fibres shall have a minimum temperature index of 155.

The covering shall have one of the following grades of thickness:

-GL1: one glass fibre covering over a bare conductor;

-GL2: two glass fibre coverings over a bare conductor:

-grade 1 GL1: one glass fibre covering (GL1) over grade 1 enamelled conductor (grade 1);

-grade 1 GL2: two glass fibre coverings (GL2) over grade 1 enamelled conductor (grade 1);

-grade 2 GL1: one glass fibre covering (GL1) over grade 2 enamelled conductor (grade 2);

-grade 2 GL2: two glass fibre coverings (GL2) over grade 2 enamelled conductor (grade 2).

Glass Fibre Wire Appearance

The fibrous covering shall be essentially smooth and continuous. And free from physical damage and foreign material when examined with normal vision, as wound on the original spool or reel. Evidence of physical damage includes gashes, broken fibre strands, and the like.

Springiness:The wire shall not exceed the maximum spring back of 5.5 degrees.

Fibre covered bare wires:The specimen shall be elongated 10%. There shall be no loss of adhesion of the fibre covering.

Fibre covered enamelled wires:The specimen shall be elongated 10%. There shall be no loss of adhesion either of the fibre covering or the enamel.

Electrical resistance:The resistance of the wire shall be expressed as the d.c. resistance at 20°C. The method used shall provide an accuracy of 0.5 %. One measurement shall be made.

Specifications – IEC 60317-32:2015 Standard

Reference standard the requirements for This part of lEC 60317 Glass fibre wound enamelled rectangular copper wire, temperature index 155.

This international standard ensures the wire meets specific performance criteria, making it reliable for use in various high-temperature applications.

NOTE For this type of wire, the heat shock test is inappropriate and therefore a heat shock temperature cannot be established. Consequently, a class based on the requirements for temperature index and heat shock temperature cannot be specified.

The range of nominal conductor dimensions covered by this standard is:

-width: min. 2,0 mm;max.16,0 mm;

-thickness: min. 0,80 mm;max.5,60 mm.

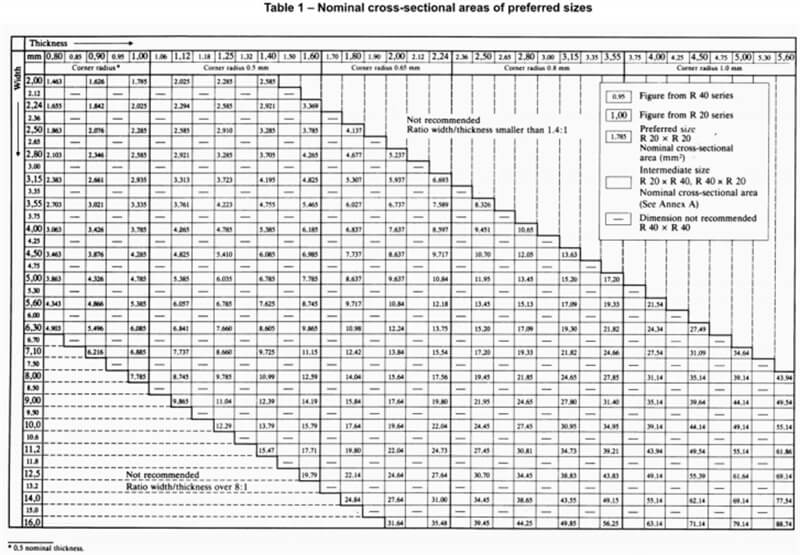

The specified combinations of width and thickness as well as the specified width/thickness ratio are according to table 1.

Conductor dimensions

The dimensions for widths and thickness of conductors of winding wires with rectangular cross-section recommended in this standard are taken from the R20 and R40 series according to lso 3.

Preferred sizes are combinations of width and thickness both according to the R20 and R40 series.

Intermediate sizes are combinations of width or thickness according to the R20 series with the other dimension according to the R40 series.

This standard covers:

– widths from 2,00 mm up to and including 16,00 mm;

– thicknesses from 0,80 mm up to and including 5,60 mm1).

The ratio width/thickness shall be greater than or equal to 1.4:1 and shall not exceed 8:1.

High-Temperature Operation: The wire can perform effectively in environments with elevated temperatures, reducing the risk of insulation failure.

Thermal Endurance: The 155 rating guarantees prolonged operation without significant degradation, extending the lifespan of the wire.

Reliability: Suitable for applications requiring consistent and reliable performance under thermal stress, such as in electric motors, generators, and transformers.

Increased Mechanical Strength: The glass fibre winding adds to the wire’s mechanical robustness, making it less prone to damage during handling and installation.

Enhanced Thermal Stability: The combination of glass fibre and enamel insulation ensures the wire can withstand higher temperatures without degradation.

Better Space Efficiency: The rectangular shape allows for more efficient use of space in electrical components, leading to improved performance and reduced size.

In short, Glass fibre wound enamelled rectangular copper wire is a highly specialized electrical wire designed for demanding applications. It combines the mechanical strength of glass fibre with the electrical insulation properties of enamelled copper wire. This type of wire is essential in applications requiring enhanced durability, thermal stability, and efficient space utilization.

Its unique combination of glass fibre winding and enamel insulation provides enhanced mechanical strength, thermal stability, and space efficiency. Therefore, it ideal for use in transformers, electric motors, generators, and inductors.

If you are interested in this type of enameled wire, please contact us.