UEW Solderable Enamelled Copper Round Winding Wire

UEW Enamelled Copper Round Winding Wire is normally used for coils and motor winding, small transformer, popular copper wire is 130, 155 or 180 uew enameled copper wire. UEW insulating layer-polyurethane resin is composed of Polyisocyanate & Polyol, which has good direct solderability from 360C to 400C.

Advantages and disadvantages

The biggest feature is that it has direct solderability, good high frequency resistance, easy coloring, and good moisture resistance. It is widely used in electronic appliances, precision instruments, telecommunications, and meters. The weakness of this product is that the mechanical strength is slightly poor, and the heat resistance is not high. , And the flexibility and adhesion of the production of large-size wires are poor, so the specifications of this product are mostly small and medium-sized wires.

Features:

(A) It has good direct solderability. During the winding process, it can avoid the action of peeling off the film, which effectively improves the work efficiency.

(B) It has good solvent resistance to the solvents and hardeners used in general containing vanilla water

Supply UEW/QA-130, UEW/QA-155, UEW/QA-180 copper enameled wire

UEW/QA-130 is an enameled round copper wire made by coating insulating varnish on the surface of copper conductors and baking and curing. The main component of the insulating varnish film is polyurethane resin.

Features: universal enameled wire; direct welding temperature 380 ℃; easy to dye; low dielectric loss under high frequency; no salt water pinhole.

Uses: coils for relays, micro motors, small transformers, magnetic heads, precision instruments, and communication equipment.

UEW/QA-155 is an enameled round copper wire made by coating heat-resistant insulating varnish on the surface of copper conductors and baking and curing. The main component of the insulating paint film is heat-resistant polyurethane resin.

Features: The softening breakdown temperature is higher than that of UEW/QA-130; the direct welding temperature is about 400℃; it is easy to dye; low dielectric loss under high frequency; no salt water pinhole.

Uses: relays, micro motors, small transformers, ignition coils, water stop valves, magnetic heads, precision instruments, coils for communication equipment.

UEW/QA-180 is an enameled round copper wire made by coating heat-resistant insulating varnish on the surface of copper conductors and baking and curing. The main component of the insulating paint film is heat-resistant polyurethane resin.

Features: The softening breakdown temperature is higher than that of UEW/Q4-155; the direct welding temperature is 420℃; it is easy to dye; low dielectric loss under high frequency; no salt water pinhole.

Uses: relays, micro motors, small transformers, ignition coils, water stop valves, magnetic heads, precision instruments, coils for communication equipment.

UEW Enamelled Copper Round Winding Wire: grade1, grade2, grade3

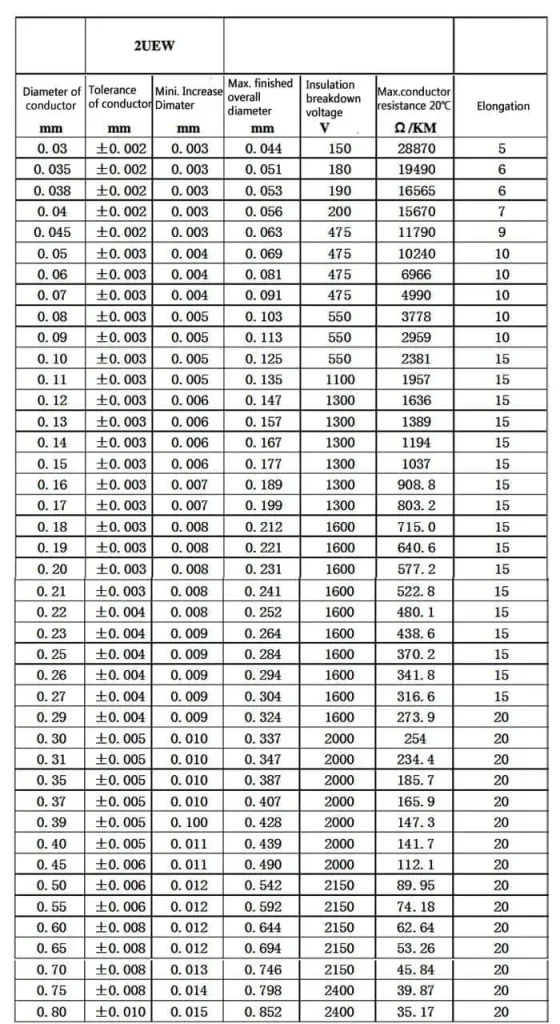

UEW Solderable Enamelled Copper Round Winding Wire specifications