Paper Covered Enameled Aluminum Wire

What is Paper-covered enameled aluminum wire?

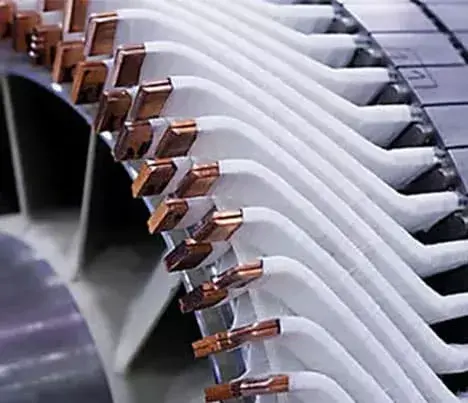

Paper-covered enameled aluminum wire(PCEAW) is a specialized type of electrical wire used primarily in the winding of transformers, motors, and other electromagnetic devices. This wire combines the properties of aluminum with insulation layers of enamel and paper to provide electrical isolation, mechanical protection, and enhanced thermal performance.

Types of Paper covered enameled aluminum wire

| Shapes | round paper covered aluminum wire, flat paper wrapped aluminum wire | |

| Insulation building | Paper covered enameled aluminum wire, paper covered bare aluminum wire | |

| Paper Layers | Single, double, triple or according to clients’ requirement | |

| Insulation materials | Telephone paper, cable paper, high-voltage paper, and turn-to-turn insulating paper | |

Specifications

| Name | Insulation Paper Winding Wire | |

| Dimension | Round | Rectangular |

| Diameter: 1.0~7.0mm | Thickness(a): 1.0~10.0mm; Width(b): 3.0~20.0mm |

|

| Insulation Paper type | Kraft electrica paper / Nomex paper / HPI-Green / Mark paper.ect. | |

| Insulation thickness | Single, double or according to your requirement | |

| Standard | IEC,NEMA,GB,JIS | |

| Packing | 30kg~150kg Poly-wooden spool (250*500/ 250*600 | |

| Appication | Oil-immersed transformer windings;medium and alrge | |

Uses, structure and types of Paper covered enameled aluminum wire

| Types | Structure | Applications | Advantages |

| Single Paper-covered Enameled Aluminum Wire | Aluminum core with a single layer of enamel coating and a single layer of insulating paper. | Suitable for low to moderate voltage applications where basic insulation is sufficient. | Cost-effective and lightweight. |

| Double Paper-covered Enameled Aluminum Wire | Aluminum core with a single layer of enamel coating and two layers of insulating paper. | Used in applications requiring higher dielectric strength and better insulation, such as medium voltage transformers and motors. | Enhanced insulation properties compared to single paper-covered wire. |

| Triple Paper-covered Enameled Aluminum Wire | Aluminum core with a single layer of enamel coating and three layers of insulating paper. | Ideal for high-voltage applications where maximum insulation is critical, such as high-power transformers and reactors. | Provides superior insulation and dielectric strength. |

| Thermally Upgraded Paper-covered Enameled Aluminum Wire | Aluminum core with a high-temperature enamel coating and thermally upgraded paper insulation. | Used in environments with high operating temperatures, such as industrial transformers and high-performance motors. | Improved thermal stability and longer lifespan under high-temperature conditions. |

| Diamond Dotted Paper-covered Enameled Aluminum Wire | Aluminum core with an enamel coating and paper insulation that has a diamond dotted pattern. The pattern typically involves resin-coated paper which forms a bond when heated, providing additional mechanical strength and stability. | Employed in applications requiring robust mechanical properties and enhanced thermal stability, such as in traction motors and heavy-duty transformers. | Enhanced mechanical stability and resistance to thermal and mechanical stresses. |

| Composite Paper-covered Enameled Aluminum Wire | Aluminum core with an enamel coating and multiple layers of different types of paper (e.g., kraft paper, crepe paper, NOMEX® paper). | Designed for specialized applications where unique combinations of properties are needed, such as high-frequency transformers or specific industrial applications. | Customized properties to match specific application requirements. |

| Presspaper-covered Enameled Aluminum Wire | Aluminum core with an enamel coating and a presspaper insulation layer, often used in high mechanical stress environments. | Ideal for applications requiring strong mechanical properties and good dielectric strength, such as power transformers and reactors. | High mechanical durability and excellent electrical insulation. |

Paper Covered Enameled Aluminum Wire – advanatges

1.Due to its high electrical, chemical and mechanical integrity, elasticity, flexibility, tear resistance, moisture and abrasion resistance, and excellent acid and alkali corrosion resistance, it will not be destroyed by insects, molds and fungi. It is compatible with all kinds of varnishes, adhesives, transformer fluids, lubricants, and refrigerants. Transformers using paper-covered wires can bring many economic, environmental and safety benefits to customers.

2. Cost Efficiency: Material Cost: Aluminum is significantly cheaper than copper, which reduces the overall cost of the wire.

Lightweight: Aluminum is lighter than copper, making the wire easier to handle and install.