Enameled Rectangular Aluminum Wire

Introduction

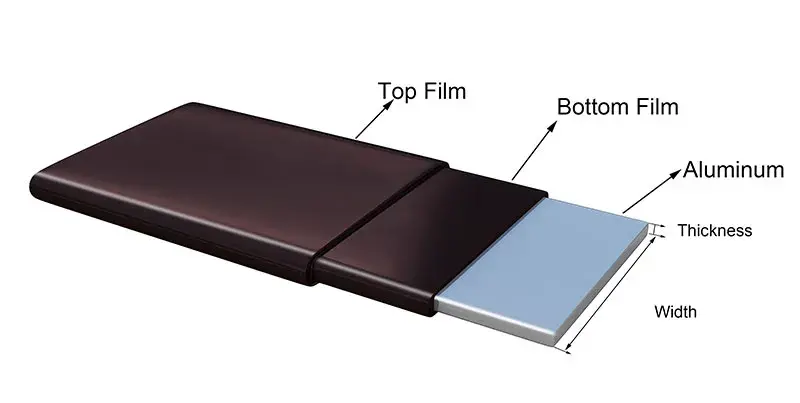

Enameled Rectangular Aluminum wire is a specialized type of wire that combines the advantages of aluminum’s lightweight and cost-effectiveness with the benefits of a flat, ribbon-like shape and an insulating enamel coating.

LP Industry Enameled Rectangular Aluminum wire specifications

| Name | Enameled Rectangular Aluminum Wire |

| Conductor | Aluminum |

| Dimension | Thickness(a):0.8-8.0mm; Width(b):2.0-22mm |

| Thermal Class | 120(Class E), 180(Class H), 200(Class C), 220(Class C+), 240(Class HC) |

| Insulation Thickness: | G1,G2 or single build, heavy build |

| Standard | IEC 60317-16,60317-16/28,MW36 60317-29 BS6811, MW18 60317-18 ,MW20 60317-47 |

| Certificate | UL |

| Packing | 30kg-150kg ply-wood spool(250*400 / 250*500/ 250*600/ 250*730) |

Features, insulations and thermal class of Rectangular Aluminum Magnet Wire:

| Thermal Class | Dimension | Type of Insulation | Heat Shock | Properties |

| 130(B) | Thickness(a):0.8-8.0mm; Width(b):2.0-22mm | Polyester | 150℃ | Shape: Flat, rectangular or square cross-section. Material: Made of aluminum, which is lighter and less expensive than copper. Insulation: Coated with an enamel insulation that provides electrical insulation and protection from environmental factors. Thermal Properties: Good thermal conductivity and heat dissipation due to the larger surface area. |

| 155(F) | Modified polyester or polyesterimide | 175℃ | ||

| 180(H) | Polyester or polyesterimide | 200℃ | ||

| 200(C) | Polyester or polyesterimide +polyamidimide | 220℃ |

Usage and structure:

Enameled Rectangular Aluminum Wire uses in manufacturing ARC welding machines. it is applicable to all types of large and medium-sized electrical machinery, dry type transformer, oil type transformers, instrument transformers, power transformers, generator, electrical motor windings, washing-machine, compressor, deflection yoke etc.

Enameled aluminium wire vs enameled copper wire

a. Compared with the copper enameled wire, enamelled aluminum magnet wire is easier to winding, also there is a solid oxide film on the surface of enameled aluminum wire, which make it has a good insulating effect, a long life.

b. Due to the good insulating effect of aluminum film layer, its heat-resistant temperature can be 20 degrees higher than the copper wire

c. The greatest benefit of using aluminum is that it is 1 / 3 lighter than copper which significantly lower the production costs, second it can attach to the solids easily, and third it can also reduce the freight and transportation during the operation.

Enameled rectangular aluminium wire vs enameled round aluminum wire

Shape: Flat vs. Round.

Surface Area: Flat wire has more surface area per unit volume.

Packing Efficiency: Flat wire can be packed more densely.

Heat Dissipation: Better in flat wire due to greater surface area.

Resistance: Flat wire typically has lower resistance per unit volume.

Flexibility: Round wire is more flexible and easier to handle.