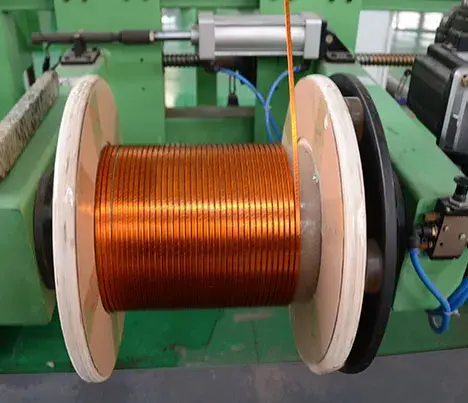

What's the Kapton Enamel?

Kapton enamel is designed for covering enameled wire and various electric heating applications. This insulating film can be laminated, metallized, punched, molded or bonded to coating Kapton is classified as thermoplastic and thermosetting plastics. Kapton polymers are responsible for polyimide thermal stability, good chemical inertness and excellent strength and stiffness. This insulating film has a unique combination of properties and is ideally suited for a variety of applications in many different industries.