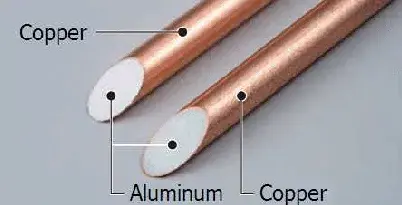

What's the Copper Clad Aluminum Wire?

Enameled wire as known as an important part of motor and cable, it is widely used in people’s livelihood and industrial fields. Copper and aluminum have been serving human life for a long ago as two extremely excellent conductive metal materials. Science and technology are progressing like wheels roll, and the rapid development is inseparable from the learning and practice of human beings. In the 1960s, copper-clad aluminum wire entered the practical stage in the electric power field in America. This is a special conductor with aluminum as the main body and copper wrapped around it. Copper-clad aluminum wire is divided into different categories according to the copper layer volume ratio (10% to 15%) and soft and hard states (soft A, hard H). It works at 130 to 220 degrees and is closely to the efficiency of copper wire. After a very short period of time, it appeared in metallurgy, petroleum, chemical industry, steel, coal and communications.