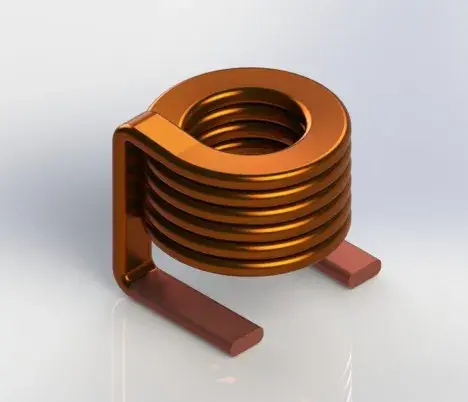

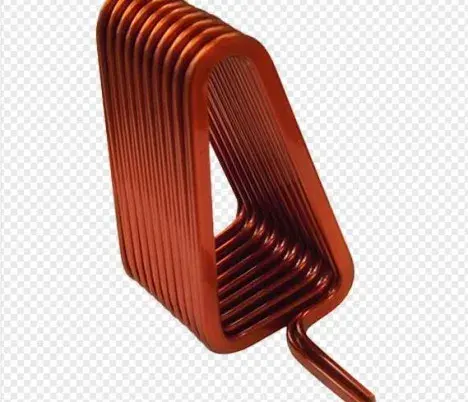

Copper strap is often used for winding field coils of large current capacity. It may be wound spirally, or helically on edge, the insulation between turns being paper for small, low-voltage, moderately cool maclchines, or asbestos tape for railway motors and the like. The edge wound form is preferred in the latter case, but where the strap is too thin it is wound spirally or flat. The construction is mechanically rugged, making it suitable for railway motors where vibration and mechanical service are severe. When insulated with asbestos, the strap copper coil is practically heat proof, but it does not cool so readily when wound fat as in the edge-wound form. In the latter type, asbestos strips are cut to shape and cemented in place with shellac. After the coil is comipletely wound it is pressed down in a steel frame and all of the infammable material burnt out with a gas fame at a high temperature, leaving a coil which is almost indestructible by heat. Since the edges of the strap are bare, this type of coil radiates heat well. In large machines where the series field is quite large, strap copper may be wound on edge with simply an air space between turns for insulation, the turns being mechanically separated at intervals by suitable spacers.