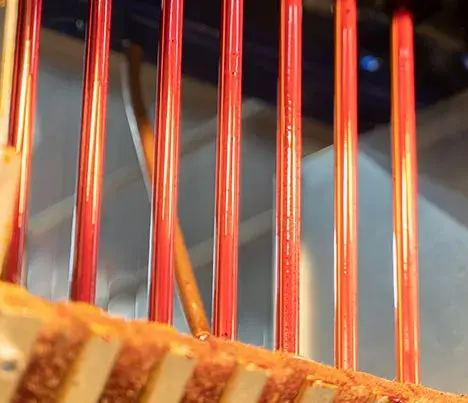

What is Enamelling Machine ?

The enamelling machine is a machine that coats the surface of metal wire with insulating paint and makes it solidify. It is an important equipment for the production of enameled wire in the electromagnetic industry. Its function is to evenly wrap a layer of insulating paint outside the processed copper wire or aluminum wire. There are a lot of diluents and organic solvents used in the production of enameled wire, mainly including benzene, xylene and cresol, which volatilize when the film is heated and cured, causing environmental pollution and energy waste. There are more and more manufacturers of enameled wire. The energy-saving and environmental protection of the enameled wire maker has become a problem that can not be ignored.