Self-Lubricating Enameled Copper Wire

Introduction

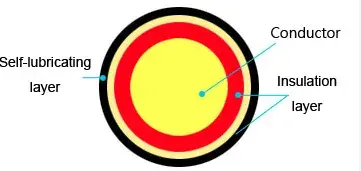

A self-lubricating enameled wire comprises a conductor and a lubricating layer. Self-lubricating enameled wire is a type of magnet wire with a special enamel coating that incorporates lubricating properties. This type of wire is commonly used in high speed windings where minimizing friction and wear is crucial.

Lubricating layer

The lubricating layer is formed around the conductor by coating and baking a coating composition, directly or through other insulating layers. The coating composition, Include 100 weight parts polyamide-imine resin, 1-5 weight parts lubricant, 1-200 weight parts isocyanate stabilized by masking agent, and 1-30 weight parts silane coupling agent, and dissolve and disperse them in a solvent.

Specifications

| Product Name | Thermal class | Standard | Size |

|---|---|---|---|

| Polyester Overcoat Polyamide Self-Lubricating Enamelled Wire | 180℃ | IEC 60317, MW 1000 | φ0.10 ~ 2.20mm |

| Polyester overcoat polyamide Self-Lubricating Enamelled Wire | 200℃ | φ0.10 ~ 5.00mm | |

| Polyamide-imide Self-Lubricating Enamelled Wire | 220℃ | φ0.10 ~ 2.20mm | |

| Polyimide Self-Lubricating Enamelled Wire | 240℃ | φ0.40 ~ 2.60mm | |

| Polyester (imide) overcoat polyamide-imide Self-Lubricating Enamelled Wire | 200℃ | φ0.50 ~ 1.40mm |

Advantages & Structure

Reduced Friction: The self-lubricating enameled wire structure is coated with some special self-lubricating material coating on the outer layer of the film, so that the friction coefficient of the wire is lower and the scratch resistance is better.

Extended Lifespan: Lower friction reduces wear and tear on the wire, extending its service life.

Enhanced Performance: Improved lubrication can lead to better efficiency and performance of electrical devices.

Ease of Handling: During winding and installation, the wire is easier to handle and less prone to damage due to reduced friction.

Heat Resistance: Some self-lubricating coatings also provide improved thermal resistance, making the wire suitable for high-temperature applications.

Applications

Auto Electricals, Home Appliances, Industrial Motors, Transformers, Fans, Pumps, Refrigeration & Air Conditioning, Defence Equipment, Railways