Where did the electric motor come from?

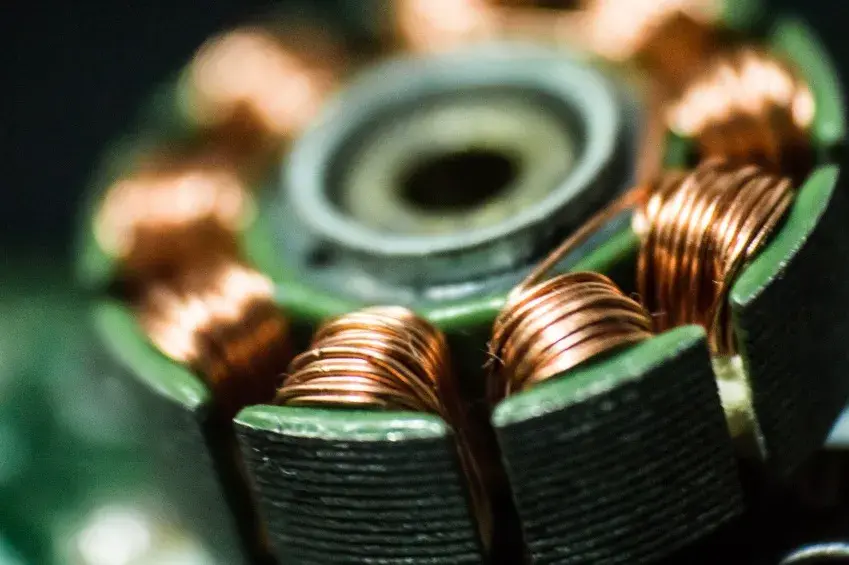

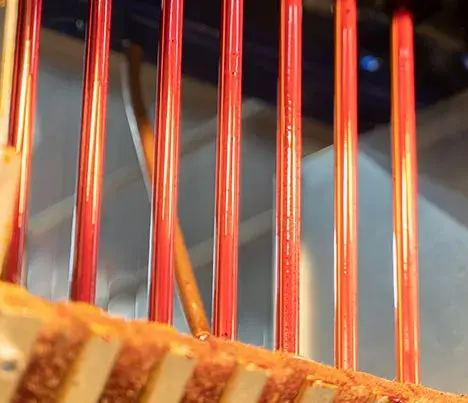

An electric motor, it is a device that converts electrical energy into mechanical energy, it works by using a conductive coil to generate a magnetic field that rotates and drives torque. According to the type of power supply can be divided into direct-current motor and alternating-current motor. Belgian inventors Gramme, Zenobe Theophile made an improved type of alternating-current motor in Paris, France in 1867, followed by a direct-current motor generator in 1869. Prior to this, Faraday and Henry theoretically determined the possibility of making a generator and made experimental products. This laid the foundation for Gramme, Zenobe Theophile to make a generator that could actually be used for industrial production, and all the history of the electric industry began with these two motors.