Technical Specifications

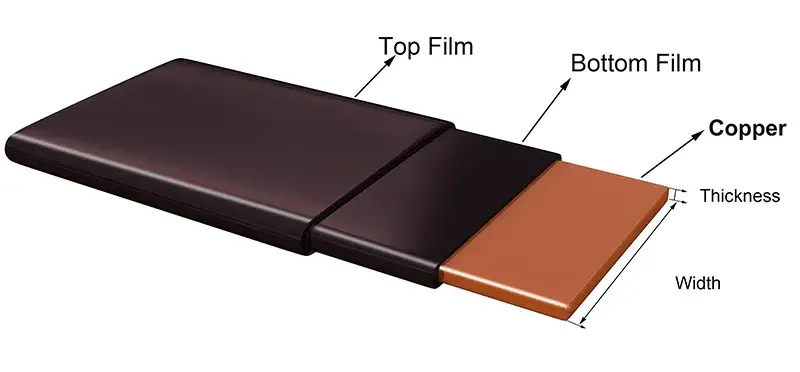

14 AWG enameled copper wire has a larger core diameter, making it suitable for applications requiring higher current transmission.

| Technical Specifications | Numerical value (approximate) | Function/Significance |

| Bare copper wire diameter | 1.628 mm (0.0641 in) | Determine the physical size and turns density of the winding. |

| Cross-sectional area | 2.08mm² | Affects current density and heat dissipation efficiency. |

| 20℃ DC resistance | 8.28 ohms/1000 feet | The resistance is extremely low, ensuring high energy transmission efficiency and low heat generation. |

| Typical current carrying capacity | 15 – 30+ amps | Suitable for coil designs requiring continuous or high peak currents. |

The low resistance of 14awg enameled copper wire minimizes resistance heat loss when the coil is working, thereby improving the overall efficiency of the equipment.