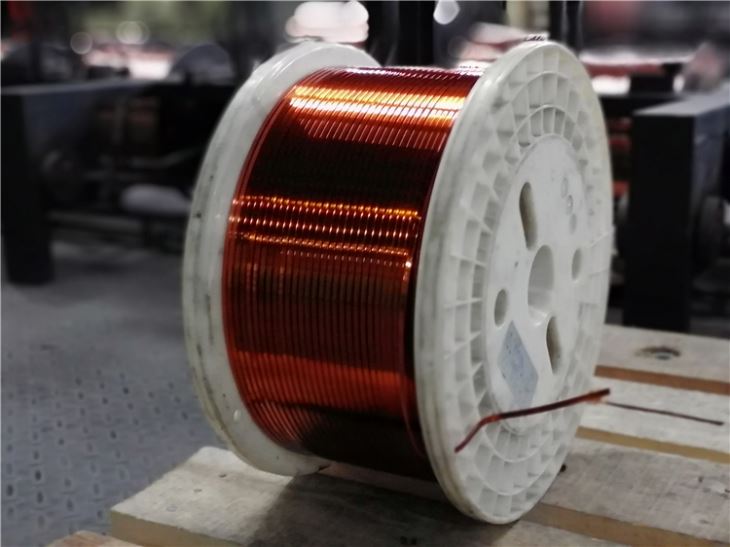

26 awg enameled copper wire

The American Wire Gauge (AWG) system is used to define the diameter of electrical wires. A 26 AWG wire has a specific diameter that determines its electrical and mechanical properties.

| Conductor diameter | Bare copper cross-sectional area | Typical resistance/20°C | Current carrying capacity |

| 0.404 mm | 0.128 mm² | 134.6 Ω/km | Typically between 1-2 amps |

Due to its moderate resistance, good flexibility, and relatively large surface area to volume ratio, 26 AWG enameled wire is very popular in applications that require a balance between space, weight, and performance.

Common Insulation Coating Types

The type of coating directly determines the wire’s temperature rating, chemical resistance, and solderability.

Polyurethane Enameled Wire

Features: Self-soldering, allowing direct soldering without prior scraping of the coating.

Temperature Rating: Typically 130°C (Class B).

Applications: High-frequency coils, inductors, speaker voice coils, and other applications requiring high soldering performance.

Polyester/Polyamide-imide Composite Enameled Wire

Features: Excellent mechanical strength, chemical resistance, and hydrolysis resistance.

Temperature Rating: Up to 155°C (Class F) or 180°C (Class H).

Applications: Motors, transformers, relays, and other products requiring high reliability and resistance to harsh environments.

26 awg enameled copper wire Applications

| Application Areas | Example | Functions and advantages |

| Motors and generators | Small DC motors, stepper motors, micro generators | The core winding material for electromagnetic energy conversion, balancing space and performance. |

| Transformers and Inductors | Essential for high-frequency transformers and power inductors in switches, chargers, and communication devices.equipment | Its fine gauge enables high-turn windings for effective magnetic energy storage and voltage transformation at high frequencies. |

| Solenoid coils and relays | Solenoid valves, contactors, relays | The driving component in relays and solenoids, where its induced magnetic field actuates mechanical switches. |

| DIY and Handmade | Motor winding for remote control models (cars, boats, airplanes) | Winding coils for small, high-speed drive motors to provide power. |

| Jewelry and Art Making | Take advantage of its flexibility and metallic color for creative weaving, wrapping, and welding. | |

| Scientific experiments and teaching | Used for homemade electromagnets, Tesla coils, etc., to demonstrate the principle of electromagnetic induction. |

How much current can 26 AWG enameled wire carry?

This is a common but complex question. Current carrying capacity (amperage) is heavily dependent on heat dissipation conditions. In an open, well-heated environment, the continuous current may be around 1.5A. In a sealed coil, it may only be able to withstand 0.5A or even less.