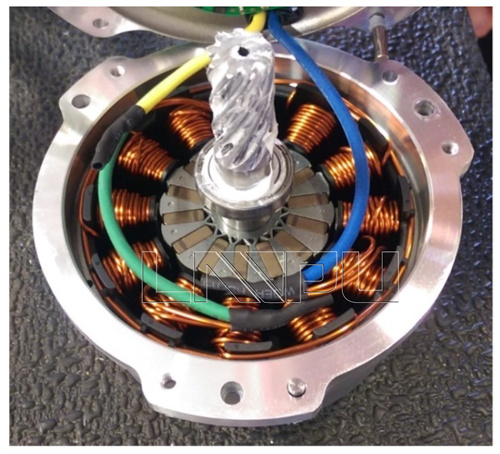

35 gauge copper winding wire online manufacture

“Gauge” here refers to the American Wire Gauge, or AWG. The larger the AWG number, the thinner the wire diameter. Copper winding wire 35 swg is a very fine bare or enameled copper wire commonly used for winding coils in inductors, transformers, relays, and motors.

Product Data

| Property | Value |

| Conductor Material | Copper (99.97% purity) |

| Diameter | 0.142 mm(approximately 0.0056 inches) |

| Cross-sectional area | 0.0159 mm² |

| resistance value/20°C | 1085 Ω/km |

| Diameter Tolerance | ±0.002 mm |

| Elongation | >20% |

| Breakdown Voltage | ≥1200 V |

| Thermal Endurance | 155°C-200°C |

| Diameter | 0.142 mm |

| Cross-sectional area | 0.0159 mm² |

| Adhesion & Flexibility | Pass |

Advantages:

Extremely high space efficiency: The extremely fine wire diameter allows for winding thousands of turns of coil on a micro-bobbin, making it a key material for miniaturization.

Achieving high inductance: More turns in the same space means higher inductance, which is crucial for high-frequency circuits and filter components.

Lightweight: Suitable for applications such as aerospace and portable devices, where weight is critical.

Excellent conductivity: Copper has excellent conductivity, second only to silver, ensuring efficient conversion of electromagnetic energy.

Flexibility: Easy to wind, capable of adapting to complex and precise winding patterns.

Precautions:

Low current carrying capacity: Due to its high resistance, it can only be used in circuits with low currents in the milliampere or even microampere range. Overcurrent can cause severe heating and burnout.

Weak mechanical strength: The wire is extremely fragile, requiring extreme patience and skill during winding, soldering, and handling, otherwise it can easily break.

High requirements for the enamel film: The enamel insulation layer is its lifeline. A tiny scratch or pinhole can cause a short circuit between turns, rendering the entire coil inoperable.

Application areas:

| Application | Core Features | Representative Products |

| High-frequency communication circuits | Manufacturing micro inductors and transformers | Mobile phones, Wi-Fi/Bluetooth modules |

| precision sensors | As a high-sensitivity detection coil | Current and displacement sensors |

| Micro electroacoustic devices | Acts as a micro voice coil to drive the diaphragm | High-end headphones and hearing aids |

| high-end medical equipment | Driving micro solenoid valves and coils | Endoscopes, implantable devices |

| Precision instruments | Windings for high-precision signal measurement | Laboratory testing equipment |

| Precision instruments | Meeting extreme space and weight requirements | Satellites, guidance systems |

How to correctly select and use 35 gauge copper winding wire?

1. Choose the appropriate type of insulating varnish:

Polyurethane: Easy to solder, no varnish removal required, suitable for automated production.

Polyesterimide: Excellent heat resistance and chemical stability, making it a general-purpose choice.

Polyamideimide: Highly heat-resistant and scratch-resistant, suitable for harsh environments.

The temperature rating of the insulation is a critical specification, often indicated by a thermal class (e.g., 155°C or 180°C), which denotes the maximum continuous operating temperature the wire can withstand without degradation.

2. Pay attention to the heat rating:

Based on your product’s operating temperature, choose wire with the appropriate heat rating (e.g., Class B 130°C, Class F 155°C, Class H 180°C) to ensure long-term reliability.

3. Careful handling and soldering:

Use a tension controller to maintain even and gentle winding tension.

Use the appropriate temperature and soldering tin when soldering. Polyurethane wire can be soldered directly, while other enameled wires may require mechanical or chemical insulation removal first.

4. Quality Control:

During incoming material inspection and production, it is recommended to use a pinhole detector to check the continuity and integrity of the paint film. This is a critical step in ensuring product yield.

35 swg copper winding wire is a seemingly small but vital material in the modern microelectronics industry.