Rectangular Enamelled Copper Winding Wire

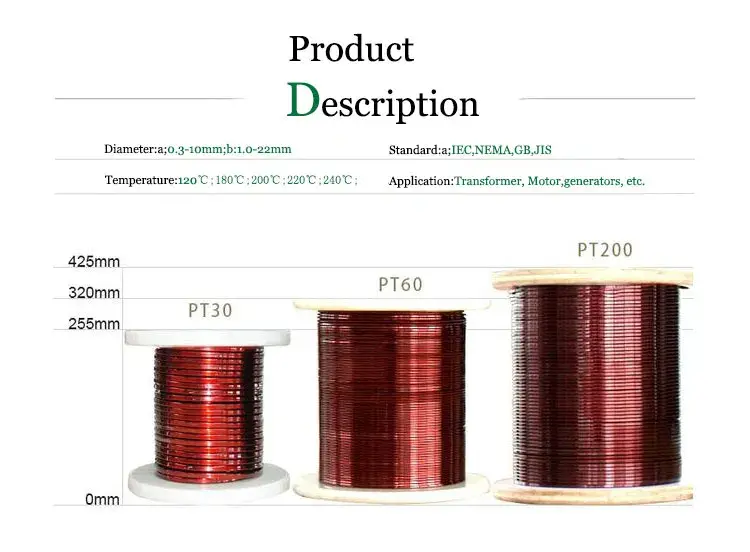

Rectangular Enamelled Copper Winding Wire is often used in the construction of transformers, inductors, and other types of electrical coils. LP Industry has the capability to produce larger transformer wires in sizes up to 22mm in width down to the smaller insulated ribbon with a thickness starting around 2mm and typically found in pancake coils. The flat enamelled copper wires are available in over 300 different dimensions from 2.0 x 0.8 to 22.0 x 8.0 mm.

The size of we supply

| Name | Enameled Rectangular Copper Wire |

| Conductor | Copper |

| Dimension | Thickness(a):0.3-10.0mm; Width(b):1.0-22mm |

| Thermal Class | 120(Class E), 180(Class H), 200(Class C), 220(Class C+), 240(Class HC) |

| Insulation Thickness: | G1,G2 or single build, heavy build |

| Standard | IEC 60317-16,60317-16/28,MW36 60317-29 BS6811, MW18 60317-18 ,MW20 60317-47 |

| Certificate | UL |

| Packing | 30kg-150kg ply-wood spool(250*400 / 250*500/ 250*600/ 250*730) |

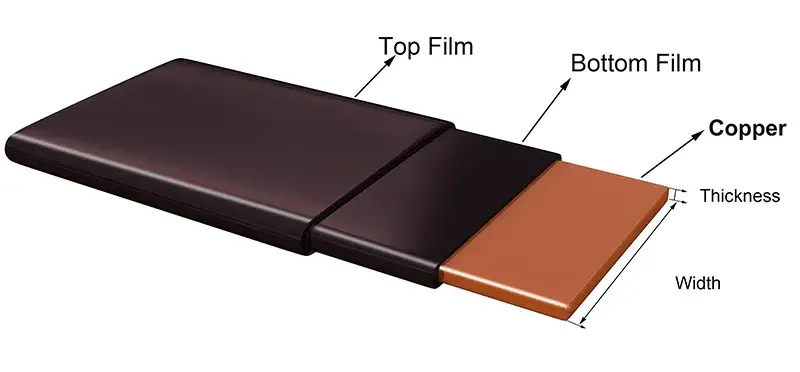

Rectangular Enamelled Copper Winding Wire structure

Features:

(a) uniformity of insulation

(b) good electrical properties like dielectric strength and insulation resistance

(c) resistance to mechanical stress

(d) resistance to chemicals, solvents, and encapsulating varnishes

(e) thermal resistance

(f) long thermal life

The enameled flat copper wire packing, such as

Uses

Rectangular enamelled copper winding wire is primarily used in applications where efficient space utilization, better heat dissipation, and mechanical stability are critical.

Power Transformers

Distribution Transformers

High-Performance Motors: such as those in electric vehicles and industrial machinery.

Large Induction Motors: Applied in large industrial motors where better heat dissipation and mechanical strength are needed.

Power Generators

Wind Turbine Generators

High-Power Inductors

Magnetic Components

Industrial Electromagnets

Scientific Instruments

Aerospace Equipment

Military Electronics

Renewable Energy Systems

Solar Power Inverters

Wind Energy Systems