Copper Square Magnet Wire

Copper Square Magnet Wire, like rectangular enamelled copper wire, is designed for specific applications where its unique properties offer advantages over round wire. It is a type of square magnet wire and designed in a wide range of square wire sizes and profiles. And mainly used in Transformer, generator, refrigeration system, class C generators, UPS power supply, electronic transformer like enameled square aluminum wire.

Copper conductor and UEW(QA), PEW(QZ), EIW(QZXY), EI/AIW(QZY) insulation materials. Spool materials: plastic, wooden.

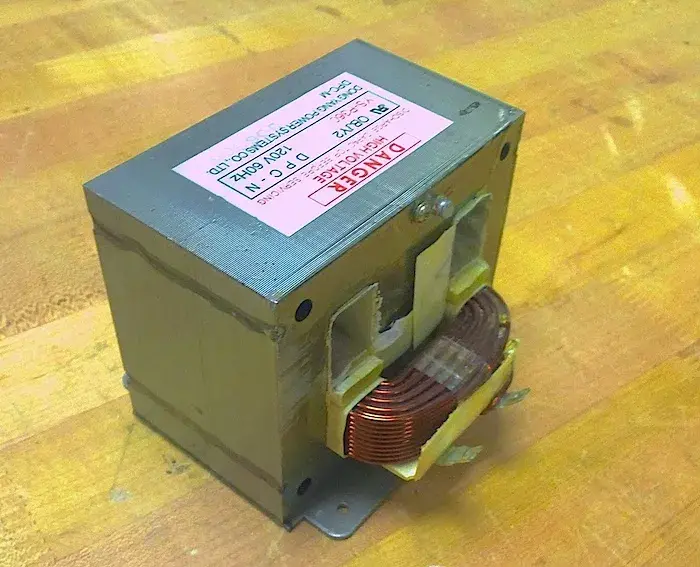

Copper Square Magnet Wire for transformer coil

Copper Square Magnet Wire technical spefications

| Name | Enameled Rectangular Copper Wire |

| Conductor | Copper |

| Dimension | Thickness(a)/Width(b):0.45-6mm |

| Thermal Class | 120(Class E), 180(Class H), 200(Class C), 220(Class C+), 240(Class HC) |

| Insulation Thickness: | G1,G2 or single build, heavy build |

| Standard | IEC 60317-16,60317-16/28,MW36 60317-29 BS6811, MW18 60317-18 ,MW20 60317-47 |

| Certificate | UL |

| Packing | 30kg-150kg ply-wood spool(250*400 / 250*500/ 250*600/ 250*730) |

Features

Square Cross-Section: Unlike round wire, this wire has a square cross-section, which allows for better space utilization.

Enamel Insulation: Coated with an enamel layer that provides electrical insulation and protects against environmental factors.

High Conductivity: Made from copper, ensuring excellent electrical conductivity.

Heat Resistance: The enamel coating is capable of withstanding high temperatures, making it suitable for demanding applications.

Mechanical Strength: The square shape offers greater mechanical stability and resistance to deformation.

Benefits

Space Efficiency: The square cross-section allows for tighter packing of windings, leading to a more compact design.

Improved Heat Dissipation: Larger surface area relative to volume enhances heat dissipation, which is critical in high-power applications.

Higher Fill Factor: The square shape reduces the gaps between wires in the winding, increasing the fill factor and thereby improving the overall efficiency of the device.

Enhanced Mechanical Stability: Provides better mechanical stability under stress compared to round wires.