Polyester Overcoated With Polyamide-Imide Enamelled Rectangular Copper Wire, Class 200

Polyester overcoated with polyamide-imide enamelled rectangular copper wire, class 200, is a high-temperature resistant wire with excellent electrical and mechanical properties.

Dimensions

the range of nominal conductor dimensions covered by this standard is:

width: min. 2mm max. 16mm

thickness: min 0.8mm max. 5.6mm

Electrical Resistance

Electrical resistance is determined by the specific dimensions, material properties, and the length of the wire. To obtain the precise electrical resistance value, it is necessary to refer to the manufacturer’s specifications.

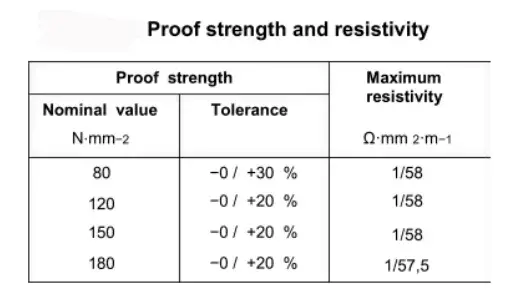

The resistance of the wire shall be expressed as the DC resistance at 20℃. The method used shall provide an accuracy of 0.5%.

The maximum value of resistance shall be not greater than the value calculated for the minimum tolerated cross-sectional area of the conductor resulting from the minimum dimensions in thickness and width and the maximum for the corner radius, and with a resistivity given in the table.

Elongation

The specific elongation value of the wire depends on various factors, including the wire gauge (thickness), the materials used, and the manufacturing process. It is important to note that the elongation properties of the wire are typically not the primary focus or specification for enamelled wires, as their main purpose is to provide electrical insulation.

Flexibility And Adherence

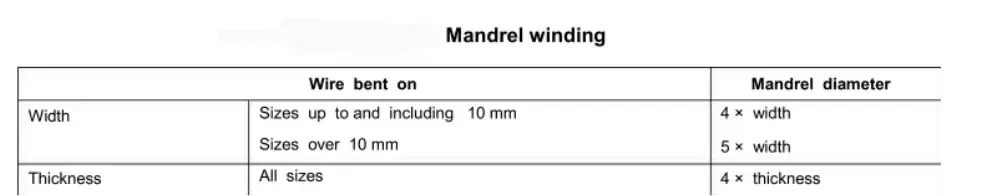

Mandrel Winding Test

the coating shall show no crack after the wire has been flatwise and edgewise on a mandrel with a diameter as specified in table.

Adherence Test

the wire shall be stretched by 15% or to the breaking point, whichever is less. The distance of loss of adherence shall be less than 1* width.

Breakdown Voltage

when tested at room temperature, at least four of the five specimens tested shall not break down at a voltage less than or equal to that given in the table, and the fifth shall not break down at less than 50% of the values specified.

when required by the purchaser, the wire shall be tested at elevated temperature.

the elevated temperature is given in the relevant specification sheet.

Solderability

Polyester overcoated with polyamide-imide enamelled rectangular copper wire, class 200, is generally considered solderable. However, the specific soldering conditions, such as soldering temperature, flux type, and solder alloy, can affect the solderability of the wire. It is important to follow the manufacturer’s recommendations and guidelines for soldering this wire to ensure proper solder joint formation.

Continuity Of Insulation

The continuity of insulation refers to the wire’s ability to maintain insulation integrity and prevent electrical leakage or breakdown under normal operating conditions.

Class 200 wire is specifically classified with a maximum allowable operating temperature of 200°C, indicating its ability to withstand higher temperature environments compared to lower-class wires. The polyamide-imide enamel coating used in the wire’s construction provides excellent thermal stability and electrical insulation properties.

To ensure the continuity of insulation, it is important to handle the wire properly, preventing any mechanical damage or exposure to harsh conditions that could compromise the integrity of the enamel insulation. Following the manufacturer’s guidelines for installation, handling, and storage is crucial to maintain the insulation quality.

These features collectively make this type enameled copper wire a highly durable, versatile, and reliable choice for industrial applications that require high temperature resistance, excellent electrical insulation, and mechanical strength.