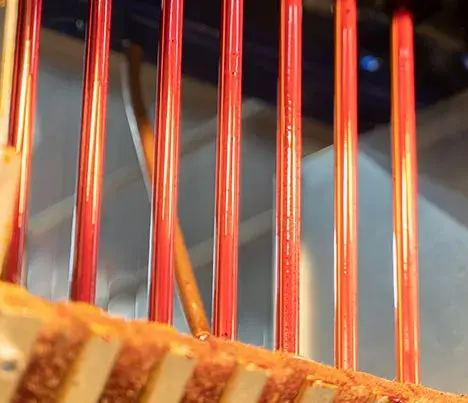

Baking Steps in Enameled Wire Production

After the wire is painted, it enters the oven. First, the solvent in the paint liquid is evaporated, then solidified to form a layer of paint film, and then painted and baked. Repeat this several times to complete the whole process of baking the enamelled package.

1. Distribution of oven temperature

The distribution of oven temperature has a great relationship with the baking of enameled wire. The distribution of oven temperature has two requirements: longitudinal temperature and transverse temperature. The longitudinal temperature requirement is curved, that is, from low to high, and then from high to low. The lateral temperature requires a straight line. The uniformity of the lateral temperature depends on factors such as equipment heating, heat preservation, and hot air convection.

The enamelling process requires that the enamelling furnace must meet

a) Accurate temperature control, ±5°C

b) The furnace temperature curve can be adjusted, and the maximum temperature in the curing zone can reach 550°C

c) The lateral temperature difference does not exceed 5°C.

There are generally three temperatures in the oven: heat source temperature, air temperature, and wire temperature. It is customary to say that the furnace temperature is measured by a thermocouple placed in the air, and the temperature is generally close to the temperature of the gas in the furnace. T source > T gas > T paint > T line (T paint is the temperature at which the paint material undergoes physical and chemical changes in the oven). Usually, T paint is about 100°C lower than T gas.

The longitudinal direction of the oven is divided into evaporation zone and solidification zone. The evaporation area is mainly for evaporating solvent, and the curing area is mainly for curing paint film.

2. evaporation

After the insulating varnish is applied to the wire, the solvent and thinner are first evaporated in a baking process. There are two forms of liquid to gas: evaporation and boiling. Molecules on the liquid surface entering the air is called evaporation, which can be carried out at any temperature, affected by temperature and density, high temperature and low density can speed up evaporation. When the density reaches a certain amount, the liquid no longer evaporates and becomes saturated. Molecules inside the liquid turn into gas and form bubbles that rise to the surface of the liquid, and the bubbles burst to release steam. The phenomenon that the molecules inside and on the surface of the liquid are vaporized at the same time is called boiling.

The paint film of the enameled wire is required to be smooth, and the vaporization of the solvent must be carried out in the form of evaporation, and boiling is absolutely not allowed, otherwise bubbles and hair particles will be generated on the surface of the enameled wire. With the evaporation of the solvent in the varnish, the insulating varnish becomes thicker, and the time for the solvent inside the varnish to migrate to the surface becomes longer. Especially for thick-gauge enameled wires, due to the thickness of the varnish, the evaporation time needs to be prolonged to avoid the internal solvent. Gasification phenomenon, get a smooth paint film.

The temperature in the evaporation zone of the oven depends on the boiling point of the solution, and the lower the boiling point, the lower the temperature in the evaporation zone. However, the temperature of the paint liquid on the surface of the wire is transmitted by the furnace temperature, plus the heat absorption of the evaporation of the solution and the heat absorption of the wire, so the temperature of the paint liquid on the surface of the wire is much lower than the temperature of the furnace.

3. to solidify

After the wire passes through the evaporation zone, it enters the curing zone. What mainly happens in the curing zone is the chemical reaction of the paint, that is, the cross-linking and curing of the paint base. For example, polyester paint is a paint film in which linear structured resins are cross-linked into a network structure. Curing reaction is very important, it is directly related to many properties of enameled wire. If the curing is not enough, it will affect the flexibility, solvent resistance, scratch resistance, softening and breakdown of the enameled wire. Sometimes although all the properties were good at that time, the stability of the paint film was poor, and after a period of storage, the performance data declined, or even failed. If the curing is excessive, the paint film becomes brittle, and the flexibility and thermal shock decrease. Most enameled wires can be judged by the color of the paint film to determine the degree of curing, but because the enameled wire is baked many times, it is not comprehensive to judge only from the appearance. When the internal curing is not enough, but the external curing is sufficient, the enameled wire has a good color, but the stripping property is poor, and the thermal aging test may cause the paint film to be sleeved or peeled off. Conversely, when the internal curing is good but the external curing is insufficient, the color of the enameled wire is also good, but the scratch resistance is poor.

During the curing reaction, the high density of the solvent gas or the humidity in the gas mostly affect the conjunctival reaction, which reduces the strength of the paint film of the enameled wire and affects the scratch resistance.

4. waste discharge

The solvent vapor and cracked low molecular substances produced during the enameled wire baking process must be discharged from the furnace in time. The density of the solvent vapor and the humidity in the gas will affect the evaporation and curing during the baking process, and the low molecular weight will affect the smoothness and brightness of the paint film. In addition, the concentration of solvent vapor is related to safety, so waste discharge is very important to product quality, safe production, and heat energy consumption.