6-Pole Motor Winding Connections

Electric motors play a crucial role in various industries and applications, from powering household appliances to driving heavy machinery. Understanding the intricacies of motor winding connections is essential for optimizing performance and ensuring efficient operation. In this blog post, we’ll delve into the specifics of 6-pole motor winding connections, shedding light on their design, benefits, and applications.

I. What is a 6-Pole Motor?

A 6-pole motor is a type of electric motor characterized by its six magnetic poles within the stator. The stator is the stationary part of the motor that houses the windings. When electric current flows through these windings, it generates a magnetic field, which interacts with the rotor (the rotating part of the motor) to produce mechanical motion.

II. Types of Winding Connections:

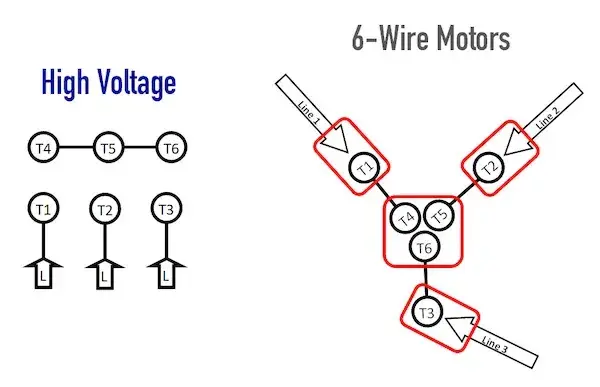

Star (Y) Connection:

In a star connection, all the winding ends are connected together to form a central point. This central point is then connected to a power source.

The star connection is known for its balanced current distribution, making it suitable for applications where the motor is subjected to varying loads.

Delta (Δ) Connection:

In a delta connection, the winding ends are connected in a closed-loop, resembling the Greek letter delta (Δ).

This configuration allows for higher voltage operation, making it ideal for applications requiring increased power output.

III. Advantages of 6-Pole Motors:

Higher Torque and Lower Speed:

6-pole motors are designed for applications that require high starting torque and lower operating speeds. They excel in scenarios where heavy loads need to be moved efficiently.

Reduced Noise and Vibration:

The six-pole configuration leads to smoother operation, resulting in reduced noise and vibration levels. This is crucial in applications where noise control is a priority.

Improved Efficiency:

These motors are known for their high efficiency, translating electrical energy into mechanical energy with minimal losses. This is especially important in energy-conscious applications.

IV. Applications:

Conveyor Systems:

6-pole motors are commonly used in conveyor systems, where they provide the necessary torque to move heavy loads along assembly lines.

Industrial Mixers and Agitators:

The high starting torque and low speed capabilities of 6-pole motors make them ideal for applications such as industrial mixers and agitators.

Pumps:

Water pumps, especially those used in agriculture and industrial settings, often rely on 6-pole motors for their ability to handle high loads.

V. Maintenance Tips:

Regular Inspections:

Routine visual inspections can help identify any signs of wear, loose connections, or other potential issues before they lead to costly breakdowns.

Lubrication:

Ensure that bearings and other moving parts are properly lubricated to reduce friction and extend the motor’s lifespan.

Temperature Monitoring:

Keep an eye on the motor’s temperature during operation. Excessive heat can be a sign of an underlying issue.

Conclusion:

Understanding 6-pole motor winding connections is crucial for optimizing performance and ensuring longevity. By selecting the appropriate winding connection and adhering to proper maintenance practices, you can harness the full potential of these motors in a wide range of applications, from conveyors to mixers and pumps. Remember, a well-maintained motor is a reliable motor, and it will serve you well for years to come.