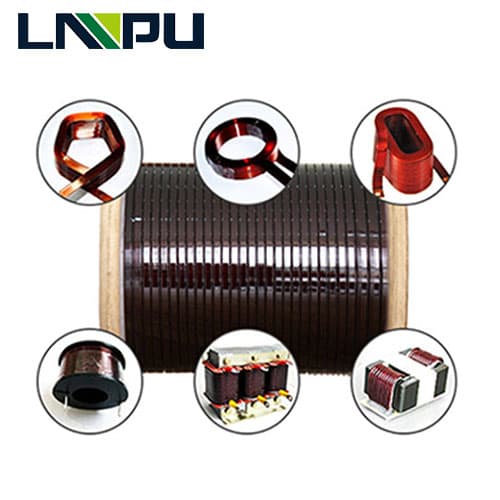

LP Industry Supply the sizes of enameled aluminum wire

| Name | Enameled Aluminum Winding Wire |

| Conductor | 99.99% pure Aluminum |

| Dimension | Round Type : diameter: 0.16-9.2mm or 1AWG – 32AWG Rectangular Type: Thickness(a):0.8-8.0mm; Width(b):2.0-22mm Square Type: Thickness(a)/Width(b):1.2-8mm |

| Thermal Class | 120(Class E), 180(Class H), 200(Class C), 220(Class C+),240(Class HC) |

| Insulation Thickness: | G1; G2 or single build; heavy build |

| Standard | IEC 60317-16,60317-25/28,MW36 60317-29 BS6811,MW18 60317-18 ,MW20 60317-47; GB/T23312.7 2009; NEMA 35 |

| Certificate | UL |

| Packing | 30kg-150kg ply-wood spool(250*400 / 250*500/ 250*600/ 250*730) |

IEC60317 Dimensions of enamelled wires – Preferred nominal conductor diameters

| Nominal conductor diameter (mm) | Conductor tolerance ±(mm) | Minimum increase due to the insulation(mm) | Maximum overall diameter(mm) | ||||

| Grade 1 | Grade 2 | Grade 3 | Grade 1 | Grade 2 | Grade 3 | ||

| 0.018

0.020 0.022 0.025 0.028 0.032 0.036 0.040 0.045 0.050 0.056 0.063 0.071 0.080 0.090 0.100 0.112 0.125 0.140 0.160 0.180 0.200 0.224 0.250 0.280 0.315 0.355 0.400 0.450 0.500 0.560 0.630 0.710 0.800 0.900 1.000 1.120 1.250 1.400 1.600 1.800 2.000 2.240 2.500 2.800 3.150 3.550 4.000 4.500 5.000 |

0.003 0.003 0.003 0.003 0.003 0.003 0.003 0.003 0.003 0.003 0.003 0.004 0.004 0.004 0.004 0.005 0.005 0.005 0.006 0.006 0.007 0.008 0.009 0.010 0.011 0.013 0.014 0.016 0.018 0.020 0.022 0.025 0.028 0.032 0.036 0.040 0.045 0.050 |

0.002

0.002 0.002 0.003 0.003 0.003 0.004 0.004 0.005 0.005 0.006 0.006 0.007 0.007 0.008 0.008 0.009 0.010 0.011 0.012 0.013 0.014 0.015 0.017 0.018 0.019 0.020 0.021 0.022 0.024 0.025 0.027 0.028 0.030 0.032 0.034 0.034 0.035 0.036 0.038 0.039 0.040 0.041 0.042 0.043 0.045 0.046 0.047 0.049 0.050 |

0.004

0.004 0.005 0.005 0.006 0.007 0.008 0.008 0.009 0.010 0.011 0.012 0.012 0.014 0.015 0.016 0.017 0.019 0.021 0.023 0.025 0.027 0.029 0.032 0.033 0.035 0.038 0.040 0.042 0.045 0.047 0.050 0.053 0.056 0.060 0.063 0.065 0.067 0.069 0.071 0.073 0.075 0.077 0.079 0.081 0.084 0.086 0.089 0.092 0.094 |

0.006

0.007 0.008 0.008 0.009 0.010 0.011 0.012 0.013 0.014 0.015 0.017 0.018 0.020 0.022 0.023 0.026 0.028 0.030 0.033 0.036 0.039 0.043 0.048 0.050 0.053 0.057 0.060 0.064 0.067 0.071 0.075 0.080 0.085 0.090 0.095 0.098 0.100 0.103 0.107 0.110 0.113 0.116 0.119 0.123 0.127 0.130 0.134 0.138 0.142 |

0.022

0.024 0.027 0.031 0.034 0.039 0.044 0.049 0.055 0.060 0.067 0.076 0.084 0.094 0.105 0.117 0.130 0.144 0.160 0.182 0.204 0.226 0.252 0.281 0.312 0.349 0.392 0.439 0.491 0.544 0.606 0.679 0.762 0.855 0.959 1.062 1.184 1.316 1.468 1.670 1.872 2.074 2.316 2.578 2.880 3.233 3.635 4.088 4.591 5.093 |

0.024

0.027 0.030 0.034 0.038 0.043 0.049 0.054 0.061 0.066 0.074 0.083 0.091 0.101 0.113 0.125 0.139 0.154 0.171 0.194 0.217 0.239 0.266 0.297 0.329 0.367 0.411 0.459 0.513 0.566 0.630 0.704 0.789 0.884 0.989 1.094 1.217 1.349 1.502 1.706 1.909 2.112 2.355 2.618 2.922 3.276 3.679 4.133 4.637 5.141 |

0.026

0.030 0.033 0.037 0.042 0.047 0.053 0.058 0.066 0.072 0.081 060.0 0.098 0.108 0.120 0.132 0.147 0.163 0.181 0.205 0.229 0.252 0.280 0.312 0.345 0.384 0.428 0.478 0.533 0.587 0.653 0.728 0.814 0.911 1.018 1.124 1.248 1.381 1.535 1.740 1.944 2.148 2.392 2.656 2.961 3.316 3.721 4.176 4.681 5.186 |

IEC60317 Dimensions of enamelled wires with a bonding layer – Preferred nominal conductor diameters

| Nominal conductor diameter mm | Conductor tolerance ± mm | Minimum increase underlying coating mm | Minimum Increase bonding layer mm | Maximum overall diameter mm | ||

| Grade 1B | Grade 2B | Grade 1B | Grade 2B | |||

| 0.020

0.022 0.025 0.028 0.032 0.036 0.040 0.045 0.050 0.056 0.063 0.071 0.080 0.090 0.100 0.112 0.125 0.140 0.160 0.180 0.200 0.224 0.250 0.280 0.315 0.355 0.400 0.450 0.500 0.560 0.630 0.710 0.800 0.900 1.000 1.120 1.250 1.400 1.600 1.800 2.000 |

0.003 0.003 0.003 0.003 0.003 0.003 0.003 0.003 0.003 0.003 0.003 0.004 0.004 0.004 0.004 0.005 0.005 0.005 0.006 0.006 0.007 0.008 0.009 0.010 0.011 0.013 0.014 0.016 0.018 0.020 |

0.002

0.002 0.003 0.003 0.003 0.004 0.004 0.005 0.005 0.006 0.006 0.007 0.007 0.008 0.008 0.009 0.010 0.011 0.012 0.013 0.014 0.015 0.017 0.018 0.019 0.020 0.021 0.022 0.024 0.025 0.027 0.028 0.030 0.032 0.034 0.034 0.035 0.036 0.038 0.039 0.040 |

0.004

0.005 0.005 0.006 0.007 0.008 0.008 0.009 0.010 0.011 0.012 0.012 0.014 0.015 0.016 0.017 0.019 0.021 0.023 0.025 0.027 0.029 0.032 0.033 0.035 0.038 0.040 0.042 0.045 0.047 0.050 0.053 0.056 0.060 0.063 0.065 0.067 0.069 0.071 0.073 0.075 |

0.002

0.002 0.002 0.003 0.003 0.003 0.003 0.003 0.003 0.003 0.005 0.005 0.005 0.005 0.005 0.008 0.009 0.010 0.010 0.010 0.011 0.012 0.013 0.013 0.014 0.015 0.016 0.016 0.017 0.017 0.018 0.019 0.020 0.020 0.021 0.022 0.022 0.023 0.023 0.024 0.025 |

0.026

0.030 0.034 0.038 0.044 0.050 0.055 0.062 0.068 0.075 0.085 0.094 0.105 0.117 0.129 0.143 0.158 0.175 0.197 0.220 0.243 0.270 0.300 0.331 0.369 0.413 0.461 0.514 0.568 0.630 0.704 0.788 0.882 0.987 1.091 1.214 1.346 1.499 1.702 1.905 2.108 |

0.029

0.033 0.037 0.042 0.048 0.055 0.060 0.068 0.074 0.082 0.092 0.101 0.112 0.125 0.137 0.152 0.168 0.186 0.209 0.233 0.256 0.284 0.316 0.348 0.387 0.432 0.481 0.536 0.590 0.654 0.729 0.815 0.911 1.017 1.123 1.247 1.379 1.533 1.738 1.942 2.146 |

Manufacturing Process of Enameled Aluminum Wire

1. Material Preparation

- Selection of Raw Material: High-purity copper or aluminum is chosen as the base material for its excellent electrical conductivity.

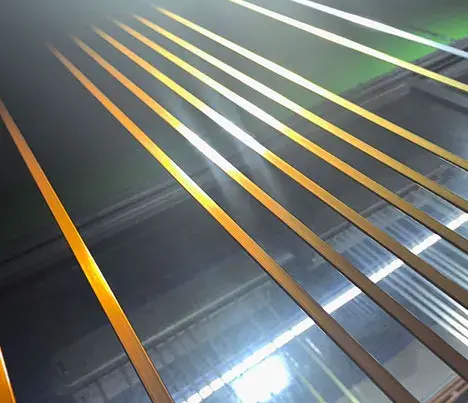

- Casting and Rolling: The raw metal is cast into rods or bars, which are then rolled into the desired flat or rectangular cross-section.

2. Drawing

- Initial Drawing: The metal is drawn through a series of dies to reduce its cross-sectional area while maintaining the flat shape. This process can involve multiple stages to achieve the required dimensions.

3. Annealing

- Heat Treatment: The drawn wire is subjected to annealing, a heat treatment process that softens the metal, relieving internal stresses and enhancing its ductility and workability.

4. Cleaning

- Surface Cleaning: The wire is thoroughly cleaned to remove any oxides, lubricants, or contaminants from its surface. This step is crucial to ensure proper adhesion of the enamel coating.

- Chemical Cleaning: Often involves an acid bath or similar chemical treatment.

- Mechanical Cleaning: May include brushing or abrasive techniques.

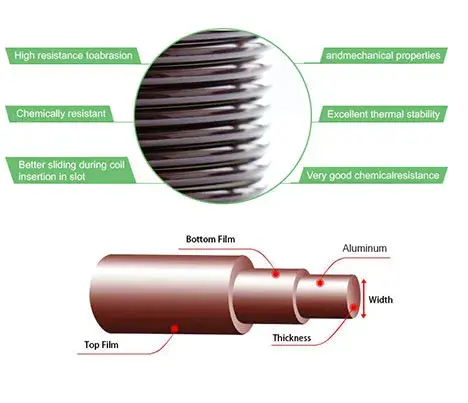

5. Enameling

- Coating Application: The cleaned wire is passed through an enameling machine where it is coated with a layer of insulating enamel.

- Dipping or Spraying: The wire may be dipped into the enamel solution or have the enamel sprayed onto it.

- Multiple Coatings: Multiple layers of enamel may be applied, with each layer being cured before the next one is applied.

6. Curing

- Heat Treatment: After each enamel application, the wire is passed through an oven or furnace where the enamel is cured. This process involves heating the wire to a specific temperature to harden and stabilize the enamel coating.

- Controlled Environment: The curing environment is carefully controlled to ensure consistent and defect-free coatings.

7. Quality Control

- Inspection and Testing: The enameled wire undergoes rigorous inspection and testing to ensure it meets all specified standards and requirements.

- Dimensional Checks: Verifying the width, thickness, and overall dimensions of the wire.

- Electrical Testing: Ensuring proper insulation resistance and dielectric strength of the enamel coating.

- Mechanical Testing: Assessing the flexibility, adhesion, and durability of the enamel.

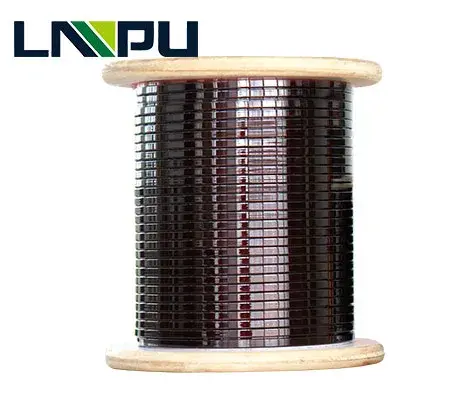

8. Spooling and Packaging

- Spooling: The finished enameled flat wire is wound onto spools or reels in preparation for storage or shipment.

- Packaging: The spools are then packaged securely to protect the wire during transportation and storage.

9. Final Inspection

- Random Sampling: Samples from each batch are taken for final quality assurance tests to ensure consistency and reliability of the product.