What is NOMEX Paper?

As an insulating material, Nomex is widely used in various electrical equipment and electronic fields that meet UL, IEC and various national and regional standards.

Nomex paper 410 was the first Nomex paper developed and one of the higher volume grades made, mostly for electrical insulation purposes.

Application

Honeycomb structures: uses in electrical laminates, like transformer cores, aircraft construction, circuit boards, Firefighting, military aviation, and vehicle racing industries.

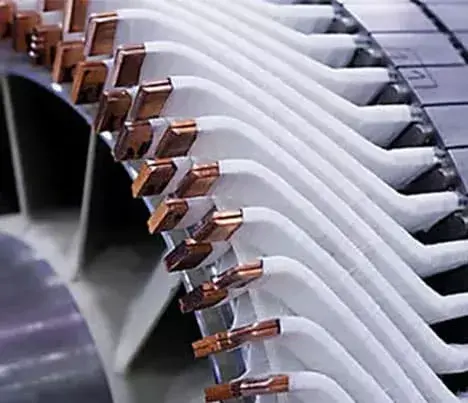

By using Nomex paper as electrical insulation, manufacturers of everything from transformers and generators to wind turbine systems and hybrid electric vehicles (HEV) have been able to help improve the integrity and performance of their own products.

Nomex has been the material of choice for electrical insulation, helping to extend the life of electrical equipment and prevent premature failures. There’s a high-quality material to address virtually any electrical insulation requirement.