What's the wire enamel insulating varnish?

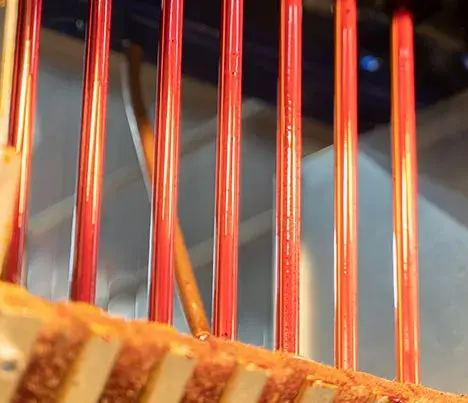

Wire enamel is a coating that creates a good insulating layer between wires in a winding. It is mainly used for the outer layer of bare copper wire, alloy wire and glass wire covered wire of various wire diameters to improve and stabilize the performance of enameled wire. It has high mechanical strength, is resistant to Freon refrigerant, has good compatibility with impregnating paint, and can meet the requirements of heat resistance, impact resistance and oil resistance. According to the heat-resistant temperature grade of insulating materials: Y (90°C), A (105°C), E (120°C), B (130°C), F (155°C), H (180°C), V (above 180°C) The main varieties of E and B enameled wires are acetal, polyurethane and polyester, and the main varieties of F and H enameled wires are polyesterimide, polyamideimide, polyester-amideimide and so on.