What's the Bondable Enamel?

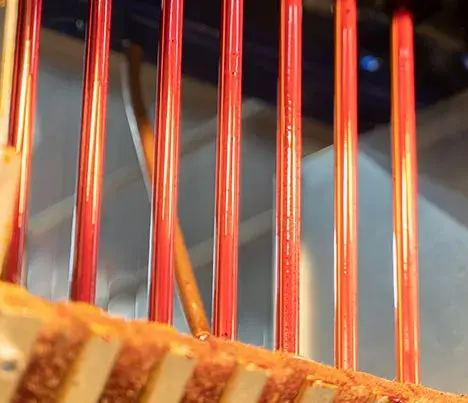

Bondable Enamel is a kind of composite material that allows inorganic glassy material to be fused onto the substrate metal and firmly bound to the metal. The lead is aluminum or copper wire. Wires contain an additional adhesive film on top of the usual insulation layer, which activates when heated, resulting in what is called a bonding wire. It comes in different types, depending on the ingredients used, such as polyamides, imides, and polyester imides. It is used to protect tight coils manufactured in applications such as inductors, transformers, motors, loudspeakers, hard disk head actuators or enameled wires.

Key Features of Bondable Enamels

- Adhesion

- Strong adhesion to base materials like metals (e.g., copper, aluminum) or non-metallic substrates.

- Bonding Capability

- Can chemically or mechanically bond with overlying materials or layers.

- Thermal and Electrical Properties

- Often used for applications requiring thermal stability and insulation (e.g., electrical wires or motors).

- Durability

- Resistant to wear, solvents, and environmental factors like moisture or heat.