Electronics and electrical appliances

Utilizing the advantages of PES, such as solder resistance, good dimensional stability, resistance to various cleaning agents, metal parts can be embedded, and good adhesion with epoxy resin, etc., it can be used as H-class insulating material in the field of electronics and electrical appliances. The main products that have been developed include coil bobbins, potentiometer casings and bases, hair dryer parts, printed circuit boards, push-button switches, thyristor insulators, electric tool motor insulators, printers, blowers, relays, etc. Coil bobbins , DIP switches, various connectors, etc. It can also be made into films of different thicknesses by extrusion molding for various electronic equipment and electrical products.

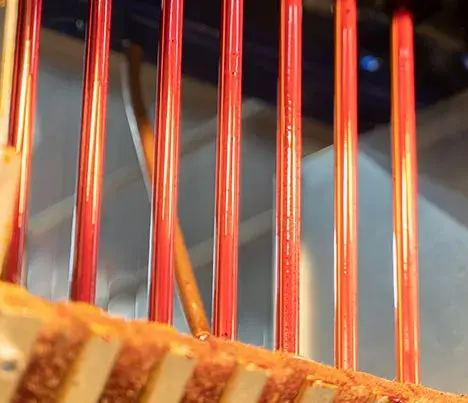

Mechanical field

Taking advantage of its high-temperature creep resistance, dimensional stability, oil resistance, and good toughness, it has been widely used in places where general resins cannot meet the requirements of use. The main products that have been developed include levers, handles, brackets, etc. of various machines, observation glasses for X-ray devices, insulators for chain saws, agricultural machinery engines, and carburetors, piston rings, heat-resistant balls, gears, copier parts, and camera parts , projector parts, industrial blower covers, automotive air-conditioning parts, arc welding torch handles, various analytical instrument components, etc.