What is the dry type transformer?

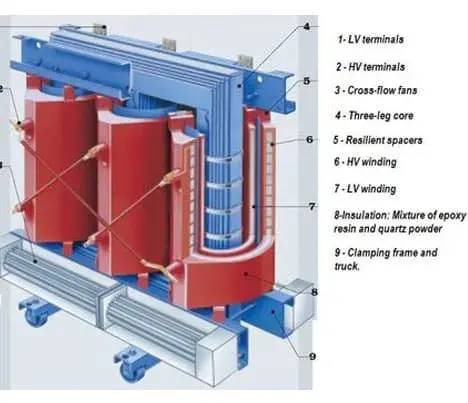

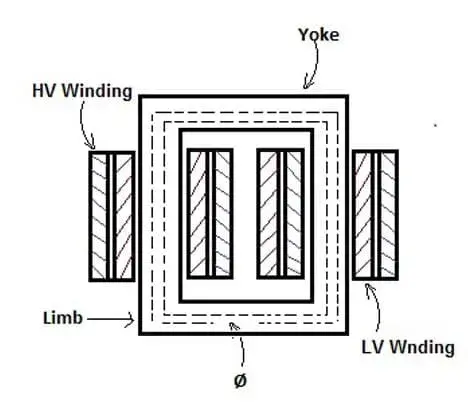

Dry-type transformers are widely used in local lighting, high-rise buildings, airports, terminal CNC machinery and equipment, etc. Simply speaking, dry-type transformers refer to transformers whose iron cores and windings are not immersed in insulating oil. Dry type transformer is mainly composed of an iron core composed of silicon steel sheets and a coil cast with epoxy resin. An insulating cylinder is placed between the high and low voltage coils to increase electrical insulation, and the coil is supported and restrained by a spacer loose performance. And the coil is supported and restrained by the spacer, and the fasteners overlapped by its parts have anti-loosening properties.

Dry-type transformers are generally suitable for power distribution, most of them have a capacity below 1600KVA and a voltage of 10KV. Some of them have a voltage level of 35KV.