Characteristics and Development of Copper-Clad Aluminum Enameled Wire

In recent years, with the deepening of the global economic integration process, the rapid development and strong market demand of the information electronics industry, cable industry and power industry have been brought about. The increasing depletion of copper resources and the continuous rise and fluctuation of copper prices have forced domestic manufacturers and users to actively look for new conductor materials that can not only guarantee product performance, but also reduce production costs to replace pure copper and reduce costs.

What is copper clad aluminum enameled wire?

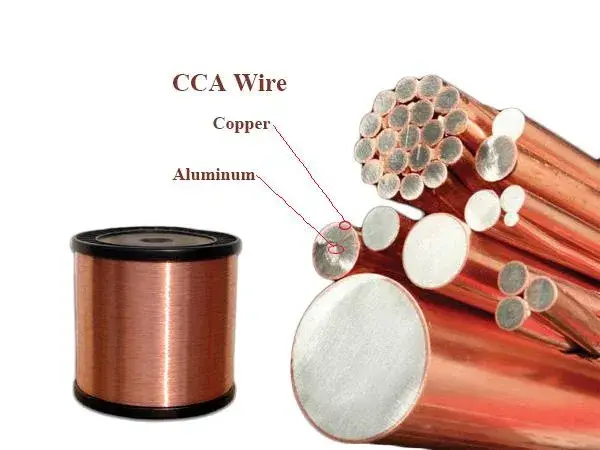

Copper-clad aluminum enameled wire is a wire with copper-clad aluminum core and coated with varnish for insulation, also known as CCA enameled wire. It usually consists of a copper layer and an aluminum layer, where the copper layer is used as the main carrier for current transmission, and the aluminum layer is used to reduce cost and weight. The enamelled layer is used to insulate and protect the wire core to prevent current leakage and short circuit.

Copper-clad aluminum enameled wire is a new type of electromagnetic wire that uses copper-clad aluminum as the inner conductor. Its characteristics are between copper and aluminum, combining the excellent conductivity of copper and the advantages of light weight of aluminum.

The development history of copper clad aluminum enameled wire

The development history of copper-clad aluminum enameled wire can be traced back to the early 20th century. Early copper-clad aluminum wires were made by mechanically pressing copper and aluminum wires together. Although this method can realize the manufacture of copper-clad aluminum wires, due to the different chemical properties of copper and aluminum, it will lead to poor contact and corrosion between them, thereby reducing the reliability and life of the circuit.

To solve this problem, in the early 1930s, researchers began using electrolysis to bond layers of copper and aluminum together. This method can form a layer of copper on the surface of the aluminum wire core, thereby improving the contact and corrosion resistance of the copper-clad aluminum wire.

With the development of electronic technology and communication technology, the demand for low-cost, lightweight and high-performance wire and cable is getting higher and higher. Beginning in the 1960s, researchers began to use enameled technology to insulate copper-clad aluminum cores to form copper-clad aluminum enameled wires. This wire has better insulation properties, lower cost and weight, and can meet the needs of some low-power applications.

In recent years, with the rapid development of electronics, communications, automobiles, aerospace and other industries, the scope of application of copper-clad aluminum enameled wire has been continuously expanded, and at the same time, technology has been continuously upgraded and improved to meet the needs of different fields.

In recent years, with the deepening of the global economic integration process, the rapid development and strong market demand of the information electronics industry, cable industry and power industry have been brought about. The increasing depletion of copper resources and the continuous rise and fluctuation of copper prices have forced domestic manufacturers and users to actively look for new conductor materials that can not only guarantee product performance, but also reduce production costs to replace pure copper and reduce costs.

The inner conductor of the copper-clad aluminum enameled wire adopts advanced cladding welding manufacturing technology, and the high-quality copper strip is concentrically clad on the outer surface of the aluminum rod core wire, and a firm interatomic metallurgical bond is formed between the copper layer and the core wire . Combining two different metal materials into an inseparable whole, drawing and annealing can be done like processing a single metal wire. During the drawing process, the diameter of copper and aluminum changes in the same proportion, and the volume ratio of copper layer remains relatively constant. Change.

Product characteristics of copper clad aluminum enameled wire

Physical properties: DC resistivity: The DC resistivity of copper-clad aluminum wire is about 1.45 times that of pure copper wire; when the resistance value is the same, the weight of copper-clad aluminum wire is about 1/2 of pure copper wire.

Electrical properties: High-frequency signals have the characteristics of “skin effect”. When transmitting high-frequency signals (greater than 5MHz), they have the same electrical conductivity as pure copper wires.

Other properties: Good plasticity, better plasticity than copper wire, no insulating oxides, easier to process. Cost saving, due to the low density of copper-clad aluminum, the unit product weight can save at least 40% compared with copper wire.

The effect of copper clad aluminum enameled wire in practical application:

Reduced cost: Compared with pure copper wire, the manufacturing cost of copper-clad aluminum enameled wire is lower, because the price of aluminum is relatively low.

Reduced weight: Since the density of aluminum is lower than that of copper, the weight of copper-clad aluminum enameled wire is relatively light, which can reduce the weight and volume of the circuit.

Good insulation performance: The enamelled layer can provide good insulation performance, thereby preventing current leakage and short circuit, and improving the reliability and safety of the circuit.

Good corrosion resistance: The copper-clad aluminum wire core manufactured by electrolysis can form a tight copper layer on the surface of the aluminum wire core, thereby improving the corrosion resistance of the copper-clad aluminum enameled wire.

Suitable for some low-power applications: Copper-clad aluminum enameled wire performs well in some low-power applications, such as electronic equipment, low-voltage power transmission and communication fields.

It should be noted that copper-clad aluminum enameled wire has higher resistance and lower conductivity than pure copper wire, so it may not be suitable for some high-power applications. In addition, the quality of copper-clad aluminum enameled wire will also be affected by factors such as manufacturing process and material quality, so it is necessary to pay attention to the brand and quality when selecting and using it.

Widely used in various large, medium and small power transformers, various machine tools, equipment transformers, various chargers, various rectifiers, etc. Applied to various electromagnetic inductance coils, such as various magnetic ring coils, various induction cooker coils, etc. Copper-clad aluminum enameled wire is widely used in high-speed motors such as water pumps, washing machines, fans, garden tools, and vacuum cleaners.