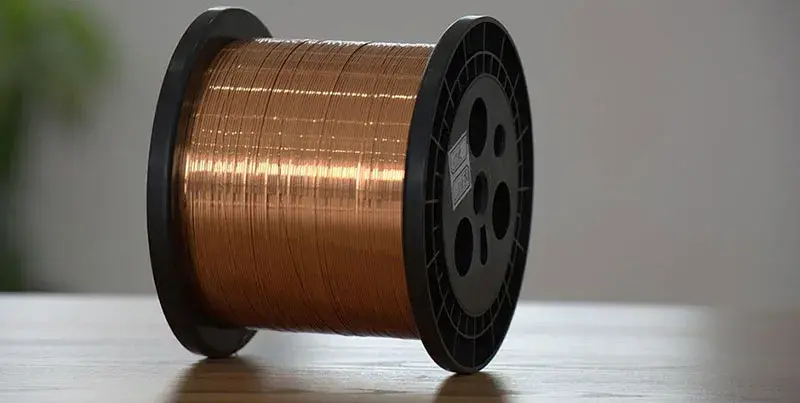

Copper Magnetic Wire with Diameter

Copper magnetic wire, also known as magnet wire, is a type of insulated copper wire specifically designed for use in electromagnetic devices such as motors, transformers, inductors, and solenoids. It consists of a conductor and an insulating layer.

Specifications

Diameter: The diameter of copper magnetic wire is critical for its electrical characteristics. It determines the current-carrying capacity, resistance, and inductance of the wire. The diameter can be specified in various units, including millimeters (mm), inches, or American Wire Gauge (AWG).

Insulation Type: The type of insulation used on the copper wire affects its thermal resistance, electrical insulation properties, and durability. Common insulation types include enamel, polyurethane, polyester, and polyimide.

Thermal Class: The thermal class of the insulation indicates the maximum temperature the wire can withstand without degrading. Typical thermal classes range from 130°C to 220°C.

| Raw material | anaerobic copper rod |

| Dimensions: | Diameter 0.025 to 0.4/ 0.45 to 7.35 /0.51 to 7.62 mm; 1 – 25 SWG, |

| Heat resistance rating | 120 (Class E); 180 (Class H); 200 (Class C); 220 (Class C+); 240 (HC Class) |

| Heat resistant thickness : | G1,G2,G3 and G4 |

| Certification system: | UL, ISO9001, ISO14001 |

| Insulation materials | cotton yarn (below 100 degrees), impregnated kraft paper (around 105 degrees), organic enamel, synthetic organic enamel (120-155 degrees), mica, glass fiber (180 degrees), polyester enamel, polyvinylformal enamel, polyester imide enamel (200 degrees). |

Common Diameters

AWG System: The American Wire Gauge (AWG) system is a standard for denoting wire diameter. Common AWG sizes for magnet wire range from 4 AWG (large diameter, high current capacity) to 40 AWG (small diameter, low current capacity).

4 AWG: Diameter of 5.189 mm (0.2043 inches)

10 AWG: Diameter of 2.588 mm (0.1019 inches)

20 AWG: Diameter of 0.812 mm (0.0320 inches)

30 AWG: Diameter of 0.255 mm (0.0100 inches)

40 AWG: Diameter of 0.079 mm (0.0031 inches)

Metric System: In the metric system, diameters are directly given in millimeters. For example:

0.1 mm

0.2 mm

0.5 mm

1.0 mm

2.0 mm

Applications Based on Diameter

Large Diameter (4-10 AWG / 2.588-5.189 mm): Used in high-current applications such as large motors, generators, and power transformers Suitable for applications requiring lower resistance and higher current-carrying capacity.

Medium Diameter (11-20 AWG / 0.812-2.588 mm): Commonly used in medium-sized motors, transformers, inductors, and relays.

Balances current capacity and ease of winding.

Small Diameter (21-30 AWG / 0.255-0.812 mm):

Ideal for small motors, electronic transformers, miniature inductors, and solenoids.

Suitable for high-frequency applications due to lower eddy current losses.

Very Small Diameter (31-40 AWG / 0.079-0.255 mm):

Used in delicate electronic components, micro-motors, and fine inductive windings.

Provides high precision and is suitable for applications with space constraints.

In conclusion, the diameter of copper magnetic wire is a crucial parameter that impacts its electrical and mechanical properties, determining its suitability for various applications. Proper selection of wire diameter and insulation type is essential for optimizing performance in electromagnetic devices.