Enameled Wire Science

Enameled wire is a type of wire that has a coating of insulating material, usually made of a polymer such as polyurethane or polyimide, applied over a metal conductor. It is widely used in various industries, including electronics, telecommunications, and power generation.

The history of enameled wire dates back to the early 20th century when the need for compact and efficient electrical devices arose. Before the development of enameled wire, insulated copper wire was used, which was bulky and required more space for installation. Enameled wire was a breakthrough in this regard as it provided a thinner and more compact option for electrical devices.

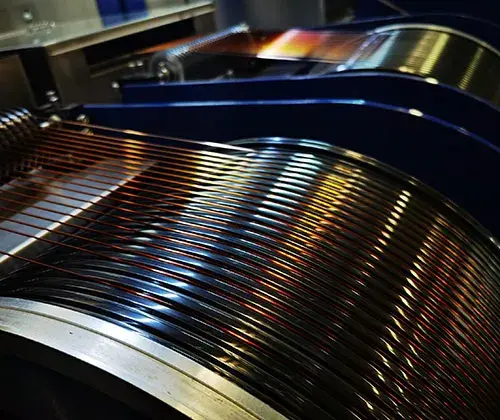

The process of making enameled wire involves coating a bare metal wire with a layer of insulating material. The wire is first cleaned and then coated with the insulating material, which is then cured using heat. The thickness of the insulation layer varies depending on the intended use of the wire. Thinner insulation layers are used for high-frequency applications, while thicker insulation layers are used for high-voltage applications.

One of the main advantages of enameled wire is its excellent electrical insulation properties. The insulation layer protects the metal conductor from external factors that could cause electrical leakage or short circuits. It also allows the wire to be used in a wide range of temperatures, making it suitable for various applications.

Another advantage of enameled wire is its flexibility. The insulation layer is usually very thin, allowing the wire to be wound into tight coils or wrapped around small objects without cracking or breaking. This flexibility makes it an ideal choice for use in motors, transformers, and other electrical devices.

Enameled wire is also resistant to abrasion and chemical exposure, which makes it durable and long-lasting. It can withstand harsh environments and still maintain its electrical performance over time.

In conclusion, enameled wire is a vital component in many electrical devices and systems. Its unique properties make it an ideal choice for applications that require flexibility, durability, and excellent electrical insulation. Its widespread use in industries such as electronics, telecommunications, and power generation highlights the importance of this technology in modern society.