Introduction to Polyamideimide

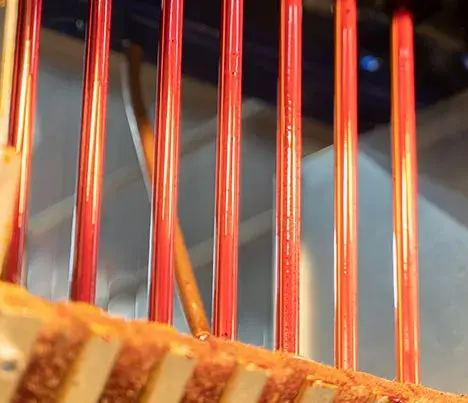

Polyamide-imide (PAI) is a thermoplastic or thermosetting non-crystalline polymer with excellent mechanical properties, heat-resistance and chemical corrosion resistance. These properties make polyamide-imide the best choice for both price and performance. As a priority, this polymer is often used as wire coating in the wire manufacturing process; polyamideimide can be obtained by gradually polymerizing isocyanate and trimellitic anhydride in N-methylpyrrolidone. As the name suggests, polyamide-imide contains both amide and imide functional groups in its molecular chain, and has the advantages of both polyamide and polyimide: high mechanical strength, melt processability, high heat resistance and excellent chemical resistance Corrosion; polyamideimide can be processed in various ways such as injection molding or pressing into various components and ingots, and can also be used as coating, fiber, film and even adhesives. Generally speaking, polyamideimide is used in the forming process The medium will be heat cured to improve the mechanical properties.