Polyester Or Polyesterimide Enamelled Round Copper Wire Overcoated With Polyamide, Class 180

Polyester or polyesterimide enamelled round copper wire overcoated with polyamide, Class 180, represents a remarkable advancement in the world of electrical engineering.

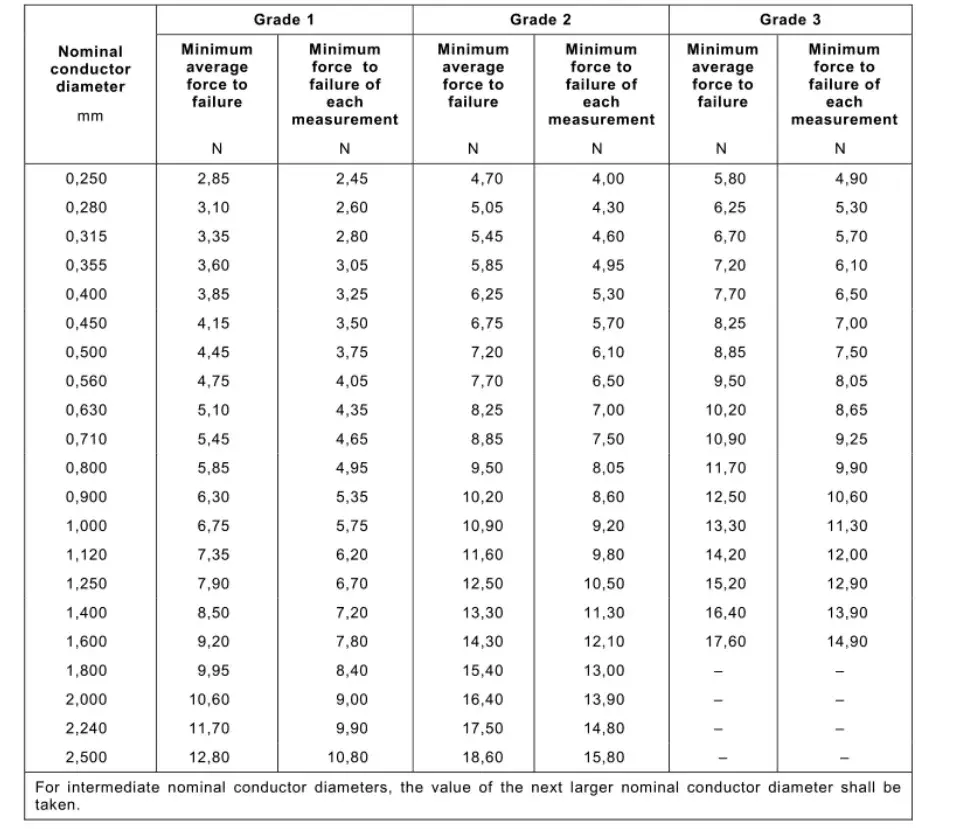

This part of IEC 60317 specifies the requirements of enamelled round copper winding wire of class 180 with a dual coating. The underlying coating is based on ployester or polyesterimide resin, which may be modified providing it retains the chemical identity of the original resin and meets all specified with requirements. the superimposed coating is based on polyamide resin.

Electrical Resistance

The electrical resistance of an enamelled round copper wire overcoated with polyamide, specifically polyester or polyesterimide enamelled wire with a polyamide overcoat (Class 180), depends on various factors such as the wire gauge (thickness), length, temperature, and the specific resistivity of the materials used.

Polyester and polyesterimide enamelled wires are commonly used as electrical conductors due to their excellent electrical properties and thermal stability. The polyamide overcoat provides additional protection and insulation.

To calculate the electrical resistance of the wire, you can use the formula:

Resistance (R) = (ρ × L) / A

Where:

ρ (rho) is the resistivity of the wire material (in ohm-meter).

L is the length of the wire (in meters).

A is the cross-sectional area of the wire (in square meters).

The resistivity (ρ) of copper is approximately 1.68 x 10^-8 ohm-meter at room temperature.

Class 180 indicates the thermal class rating of the wire, which means it is designed to withstand temperatures up to 180°C. However, the actual electrical resistance can vary with temperature due to the temperature coefficient of resistance (TCR) of the wire material.

Elongation

The specific elongation value of the wire depends on various factors, including the wire gauge (thickness), the materials used, and the manufacturing process. It is important to note that the elongation properties of the wire are typically not the primary focus or specification for enamelled wires, as their main purpose is to provide electrical insulation.

Springiness

The springiness, also known as the “elasticity” or “resilience,” of polyester or polyesterimide enamelled round copper wire overcoated with polyamide (Class 180) refers to its ability to return to its original shape after being deformed or stretched.

The springiness of the wire can depend on various factors, including the wire gauge (thickness), the specific materials used, and the manufacturing process. However, it’s important to note that the primary focus of enamelled wires is their electrical insulation properties rather than mechanical characteristics.

Flexibility and Adherence

See clause 8 of IEC 60317-0-1, where the constant K used for the calculation of the number of revolutions for the peel test shall be 110mm

Heat Shock

where the minimum heat shock temperature shall be 200℃

Cut-through

no failure shall occur within 2 min at 265℃

Resistance To Abrasion

The specific resistance to abrasion can vary depending on the thickness and quality of the polyamide overcoat, as well as the specific manufacturing processes employed.

nominal conductor diameters from 0.25mm up to and including 2500mm