Introduction

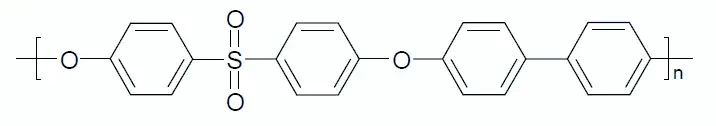

Polyphenylsulfone (PPSF or PPSU) is a high performance polymer made of aromatic rings linked by sulfone (SO2) groups. Polyphenylsulfone (PPSU, PPSF) is an amorphous, heat-resistant and transparent high-performance thermoplastic synthesized by nucleophilic aromatic substitution between difluorodiphenyl sulfone and the sodium salt of 4,4-dyhydroxybyphenyl with elimination of sodium fluoride. The biphenylene ether unit of PPSU markedly increases the impact strength and reduces the notch sensitivity, resulting in high notched (Izod) impact values which exceeds those of other polysulfones (PSU, PES).2 It also contributes to ease of melt fabrication. In fact, these resins can be readily injection molded or extruded on conventional equipment. However, processing requires relative high mold temperature of at about 365 to 395°C whereas glass fiber reinforced grades require even higher temperatures.