Introduction to Polyurethane Enamels

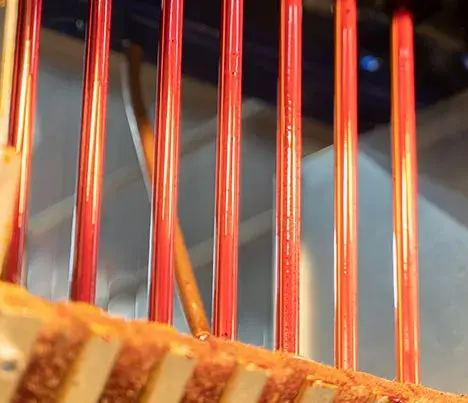

Polyurethane Enamels is coated on the surface of copper wire or aluminum wire. After baking, it can form a kind of product with electrical insulation and certain mechanical strength, heat resistance and chemical resistance. It is mainly used for electromagnetic wire manufacturing. Some products may also have other uses, such as the production of decorative metal wires, or other insulating and heat-resistant coatings. Polyurethane paint is one of them, let’s take a look at this kind of paint today.

Polyurethane paint is polyurethane paint. It has strong paint film, full luster, strong adhesion, water resistance, wear resistance and corrosion resistance. It is widely used in high-grade wooden furniture and can also be used on metal surfaces. Its shortcomings mainly include problems such as foaming when it is wet, and powdering of the paint film. Like polyester paint, it also has the problem of yellowing.