Self-bonding Magnet Wire: Production, Considerations, and Applications

Self-bonding magnet wire is a specialized type of enameled wire widely used in electrical and electronic applications. Unlike traditional magnet wire, self-bonding magnet wire possesses a unique property that allows it to adhere to itself without the need for additional bonding agents, such as adhesives or solvents. This characteristic makes it highly advantageous in various industries where the elimination of extra steps and materials is desirable.

What is Self-bonding Magnet Wire?

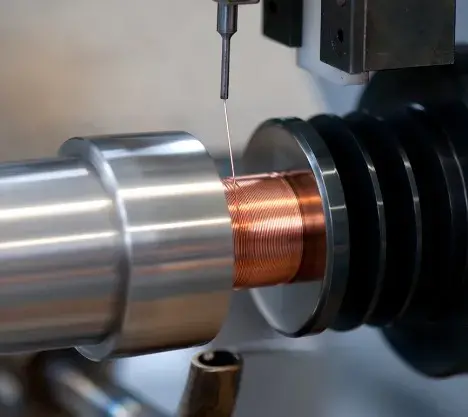

Self-bonding magnet wire, also known as self-lapping wire, is an enameled wire designed with a special coating that enables it to self-adhere when wound around itself. This eliminates the need for additional bonding agents during the manufacturing process, simplifying the overall production and enhancing the wire’s reliability. The enameled insulation ensures that the wire maintains electrical isolation, while the self-bonding property creates a strong bond that holds the wire in place without the risk of unwinding.

Production Process of Self-bonding Magnet Wire:

The production of self-bonding magnet wire involves several key steps:

a. Wire Drawing: The manufacturing process begins with wire drawing, where copper or aluminum is drawn through a series of dies to achieve the desired gauge and diameter.

b. Enameling: The wire is then coated with a thin layer of insulating enamel. This enamel must have specific characteristics, such as good adhesion to the wire’s surface and the ability to bond to itself.

c. Baking: After enameling, the wire passes through a baking process to cure the enamel coating and ensure its durability.

d. Self-bonding Treatment: This critical step involves subjecting the wire to a controlled treatment that activates the self-bonding property of the enamel. The treatment process can vary depending on the specific type of enamel used and the desired bonding strength.

e. Cooling and Testing: The wire is allowed to cool, and various tests are conducted to ensure it meets the required electrical and mechanical specifications.

Considerations during Manufacturing:

To achieve high-quality self-bonding magnet wire, manufacturers must pay attention to the following considerations:

a. Enamel Selection: The choice of enamel is crucial, as it directly impacts the wire’s self-bonding capability and overall performance. Proper adhesion to the wire surface and compatibility with the self-bonding treatment are vital aspects to consider.

b. Consistency in Treatment: The self-bonding treatment process must be performed consistently to ensure uniform bonding strength across the wire.

c. Wire Cleanliness: Prior to enameling, the wire surface must be clean and free from any contaminants that could hinder the bonding process.

d. Quality Control: Rigorous quality control measures should be implemented throughout the production process to identify and address any defects or variations that may compromise the wire’s performance.

Applications of Self-bonding Magnet Wire:

Self-bonding magnet wire finds applications in various industries due to its unique properties:

a. Motors and Transformers: Self-bonding magnet wire is extensively used in electric motors and transformers, where its self-adhesive nature ensures the winding stays intact during operation, reducing the risk of mechanical failures.

b. Solenoids and Coils: The wire’s ability to bond to itself makes it an ideal choice for solenoids and coils, ensuring stability and consistent performance.

c. Electronics and Appliances: Self-bonding magnet wire is employed in various electronic components and appliances, providing reliable electrical connections.

Self-bonding magnet wire offers a versatile solution for electrical and electronic applications, simplifying production processes and enhancing the reliability of wound components. With careful consideration during manufacturing and adherence to quality control measures, this specialized wire continues to play a crucial role in numerous industries, contributing to the advancement of technology and electrical engineering.

More interested, you can see the related blog “Self-bonding copper wire”.