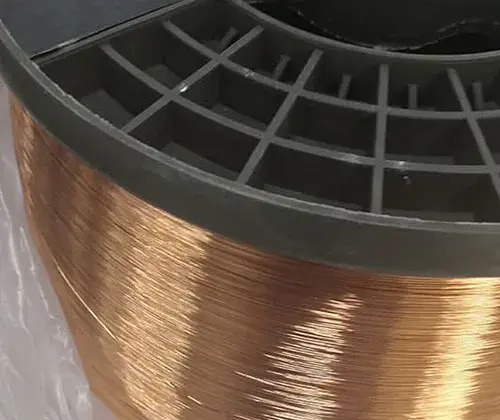

Shipped The Cu Clad Al Wire To America

On 2021-10-16, LP Industry shipped the 0.32mm Cu clad al wire which also can be written in cu clad al wire to America. The thermal class is 180℃,we also provide the 155℃ and 200℃.

Characteristics of copper clad aluminum wire

1. Structural parameters

According to the volume ratio of the copper layer, it can be divided into two types: 10% and 15%. The copper-clad aluminum wire with the copper layer volume ratio of 15% is mainly used for the inner conductor of the coaxial cable for transmitting high-frequency signals, and the 10% copper-clad aluminum wire Mainly used to transmit low-frequency current cable conductors.

According to the weight of the copper layer, it can be calculated that the copper-clad aluminum wire with a copper layer volume ratio of 10% and 15% has a copper layer weight ratio of 26.8% and 36.8, respectively. In addition, according to its use state, it can be divided into two types: soft state (Type A) and hard state (Type H).

Physical properties

⑴ Density

For a copper-clad aluminum wire with a copper layer volume ratio of 15%, its density is 3.63gcm3; and a copper-clad aluminum wire with a copper layer volume ratio of 15% has a density of 3.32gcm3. Due to the low density of copper-clad aluminum wire, copper-clad aluminum wire has many advantages:

①Compared with copper-clad aluminum wire of pure copper wire of the same weight and wire diameter, the length of copper-clad aluminum wire is about 1.7 to 2.5 times that of pure copper wire, which will reduce material costs for manufacturers.

② Since the weight of copper in 1 ton of copper-clad aluminum wire is 268-368Kg, it can replace 1.7-2.5 tons of pure copper wire, so that the use of copper-clad aluminum wire can save a lot of copper resources.

⑵Specific heat

According to the thermodynamic formula Q=cm(t2-t1), since the specific heat of pure copper wire is c=0.092Kcal/kg.k, the specific heat of copper-clad aluminum wire is c=0.149Kcal/kg.k, which means that the copper clad The specific heat of aluminum wire is much larger than that of pure copper wire. Therefore, the temperature of the copper clad aluminum wire of the same weight needs more heat than that of pure copper wire to increase the temperature by 1 degree, so that the copper clad aluminum wire has Lower temperature, which is of great benefit to the safe use of electricity.

⑶ Conductivity

The resistivity of copper-clad aluminum is larger than pure copper wire and smaller than that of aluminum. The DC resistivity of copper-clad aluminum wire with a volume ratio of 10% and 15% at 20°C is ≤0.02743Ωmm2/m and ≤0.02676Ωmm2/m, respectively. Therefore, according to the International Electrotechnical Regulations, the electrical resistivity of annealed industrial copper at 20°C is equal to 0.017241Ωmm2/m as the standard conductivity, expressed as 100% IACS, then the conductivity of copper-clad aluminum is about 65% IACS.