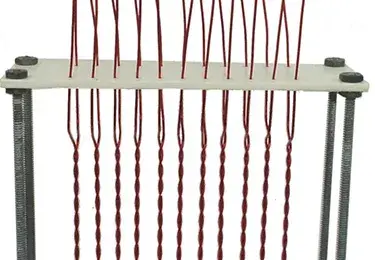

THEIC Modified Polyesterimide Wire Enamels

is class 180 THEIC modified polyesterimide wire enamel with temperature index 200.

provides improved flexibility & adherence to copper.

gives excellent resistance to refrigerants hermetic motors.

can be used as base coat for manufacturing dual coating wires with Polyamide-Imide.

suitable for high speed enamelling machines up to 200VD.

Theic modified Polyesterimide enamel used as a single coat as well as for dual coat wires. It is recommended for thicker gauges. Wires combined with Polyamide – Imide enamel have excellent resistance against chemicals including refrigerants & suitable for application in hermetic motors.