Unlocking the Power of Enameled Copper Wire: A Comprehensive Guide to Specifications

In the world of electrical engineering, the term “enameled copper wire” might not be unfamiliar. This unassuming component plays a pivotal role in countless applications, from power generation to consumer electronics. Enameled copper wire, also known as magnet wire, finds its application in transformers, motors, inductors, and various other devices where efficient energy transfer is essential. The key to harnessing its potential lies in understanding its specifications.

What is Enameled Copper Wire?

Enameled copper wire is essentially a copper conductor coated with a layer of enamel insulation. The enamel serves as a dielectric insulation that prevents direct electrical contact between the copper wire and its surroundings. This coating allows for efficient energy transmission while minimizing the risk of short circuits.

Key Specifications to Consider

When selecting enameled copper wire for a specific application, it’s crucial to consider various specifications to ensure optimal performance and longevity. Let’s delve into the essential specifications to keep in mind:

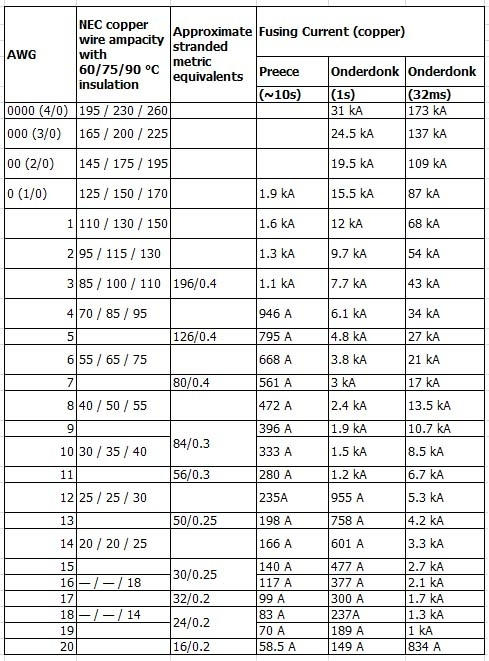

1. Gauge (AWG)

The gauge of enameled copper wire refers to its diameter. It’s typically denoted using the American Wire Gauge (AWG) system, which assigns a specific number to each gauge. A lower AWG number indicates a thicker wire. The choice of gauge depends on the current-carrying capacity and available space within the application.

2. Insulation Type and Thickness

Enameled copper wires come with different types of insulation materials, such as polyester, polyurethane, polyimide, and more. Each type offers distinct electrical, thermal, and mechanical properties. The insulation thickness affects the overall diameter of the wire and its ability to withstand voltage stress.

3. Temperature Rating

The temperature rating of enameled copper wire refers to the maximum temperature the wire’s insulation can handle without degrading. This specification is crucial for applications that involve high temperatures, as exceeding the temperature limit can lead to insulation breakdown and failure.

4. Thermal Class

Enameled copper wires are classified into thermal classes based on their temperature rating. Common thermal classes include Class 130, Class 155, Class 180, and Class 200, where the numbers represent the temperature in degrees Celsius that the wire can withstand for extended periods.

5. Electrical Resistance

The electrical resistance of enameled copper wire depends on its gauge and length. Lower resistance allows for efficient energy transfer with minimal loss. It’s important to consider resistance, especially in applications where energy efficiency is a priority.

6. Dielectric Strength

Dielectric strength refers to the maximum voltage a wire’s insulation can withstand before breaking down. This specification is crucial in high-voltage applications to prevent insulation failure and potential short circuits.

7. Flexibility and Formability

Some applications require enameled copper wire to be bent, twisted, or wound into specific shapes. The wire’s flexibility and formability are essential considerations to ensure it can be easily manipulated without damaging the insulation.

8. Environmental Considerations

Depending on the application’s environment, enameled copper wire may need to withstand exposure to moisture, chemicals, or UV radiation. Choosing the right insulation material is crucial to ensure the wire’s longevity and performance under such conditions.

Conclusion

Enameled copper wire is an unsung hero of the electrical engineering world, enabling efficient energy transfer in a wide range of applications. Selecting the right wire involves a careful consideration of specifications such as gauge, insulation type, temperature rating, and more. By understanding these specifications and tailoring your choice to the specific requirements of your application, you can unlock the full potential of enameled copper wire and ensure the success of your project. Whether you’re building a transformer, designing a motor, or working on any other electrical device, enameled copper wire specifications will be your guiding light.